Product Suppliers

Service Providers

Projects & Bids

News & Events

Tools & Resources

RNG Forum 2025

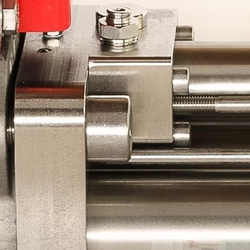

Check Valve Bray-Rite

Celebrating 30 Years | 1986-2016

At Bray, our business is helping our customers with their flow control requirements. Our modular product line of valves, actuators, and accessories offer the best compatibility, economy, and quality performance in the flow control industry.

Contact Bray Controls

Related products

SWG 100 BIO EX Stationary Biogas Analyzer

Multitec 560 for gas warning and measuring

BPC® Go

SWG 100 BIOGAS Compact Analyzer

HygroPro Transmitter

Multitec BioControl 2 for stationary and mobile gas measuring

Fitec Automated Bicarbonate Analyzer

400GD / 500GD Multifunctional Detector and Measuring Device

Automatic Methane Potential Test System (AMPTS®)

SEWERIN Gas Detection - Service & Calibration

XMO2 Thermo Paramagnetic Oxygen Analyser

Gas Detection