Automatic Methane Potential Test System (AMPTS®)

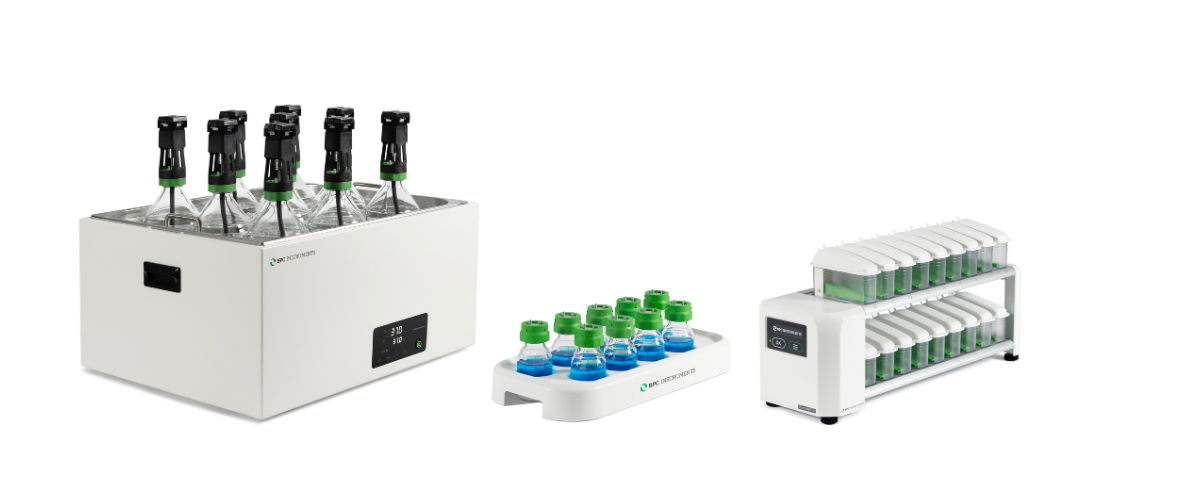

The Automatic Methane Potential Test System (AMPTS) is the market-leading analytical tool for anaerobic batch fermentation testing. Now on its third generation, AMPTS III is automated and fully integrated for easy access to sampling, analysis, recording and report generation. AMPTS III houses 18 glass reactors for tests in its standard form, or your can choose the slimmed down AMPTS III Light, which houses 9 glass reactors.

Files

Product Description

What is the AMPTS

AMPTS is the analytical tool preferred by scientists and engineers for conducting anaerobic batch fermentation tests. The latest generation of AMPTS comes in two models (AMPTS III and AMPTS III Light) that house 18 or 9 test vials, respectively. AMPTS III automates and simplifies a wide range of testing, including biochemical methane potential (BMP) tests, biogas potential, anaerobic biodegradability studies, specific methanogenic activity (SMA) assays, and residual gas potential (RGP) analyses on digested slurry. With either AMPTS III model, sampling, analysis, recording and report generation are fully integrated to offer users a seamless testing experience.

AMPTS III

AMPTS III Light

Product Features

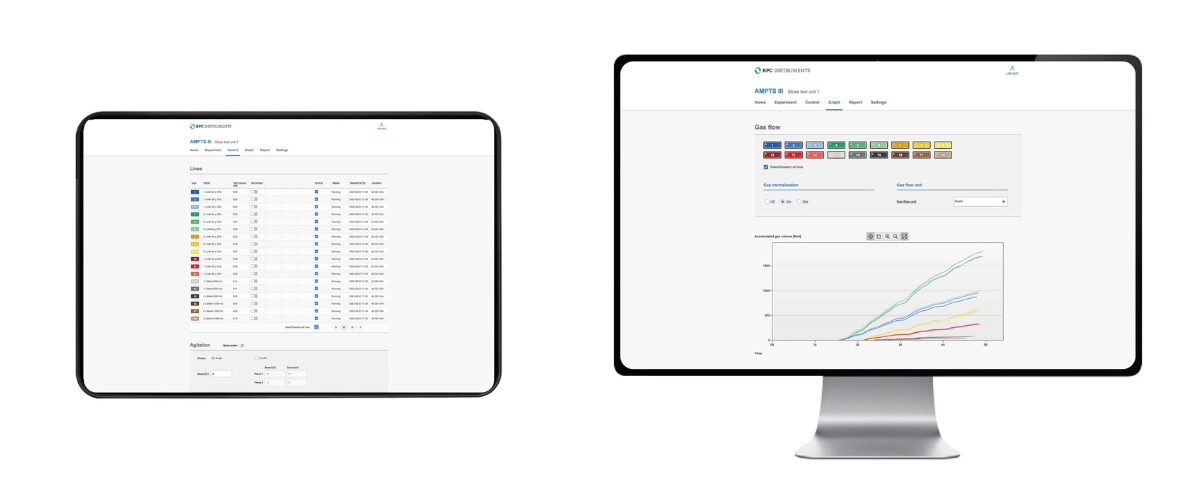

- Web-based. User friendly web-based software running on an embedded server. No need for software installation on PC, tablet or smartphone

- Remote access. AMPTS can be accessed remotely and locally from any device with a web browser

- Automated. Automatic real-time pressure, temperature and moisture compensation

- Calibration free

- Multiplexing potential. Possibility of multiplexing allows for simultaneous batch analysis at different start-up times

- Easy maintenance. Modular design means most parts can easily be exchanged

- Local data storage. Data stored on the local instrument means no dependence on external computer

- Easy processing. Data exported as a spreadsheet for further analysis with uniform time axis for easy data processing

- High data storage capacity. 7200 l of gas per channel

- Real-time measurements. Measure several gas types, including biogas, in real time

- Gas composition estimates. Connect in series to get real time estimates of gas composition

- Effective agitation. Proven strong, reliable, multifunctional agitation

- Outputs in various time intervals. Generates outputs ranging from a datapoint every minute to one every day

Robust operations with modular design

AMPTS is designed and manufactured in Sweden, adding the best elements of Scandinavian form and function to quality and reliability. AMPTS ensures no data is lost, even if the entire system goes down. The modular design makes the maintenance of AMPTS easy because many parts can be exchanged without sending the instrument to a workshop.

Determine the true biogas and methane potential

AMPTS allows you to determine the true biogas and methane potential as well as dynamic degradation profile of any biomass substrate. That means you can more easily determine the optimal retention time and mix of substrates for co-digesting, screen proper pre-treatment methods, evaluate the need for additives, and even assess the biological performance of an individual biogas digestor or process configuration.

Results from anywhere on any device

AMPTS is designed to allow easy access from a remote location using any device with a web browser. Monitor your experiment from your office and home with your computer, tablet or phone of choice. You can also expand the analytical capacity of AMPTS easily by connecting multiple instruments together with an Ethernet switch. With this feature, each AMPTS can be operated as a stand-alone device or connected in parallel, depending on your needs.