Fitec Environmental Technologies Inc.

With over 30 years of experience and biogas plants on three continents, Fitec Environmental Technologies offers holistic biogas systems and support for a range of markets in the organic waste and anaerobic digestion industries in North America. Learn how Fitec’s advanced design and engineering can help you. Visit www.fitec.ca.

Description

About Fitec

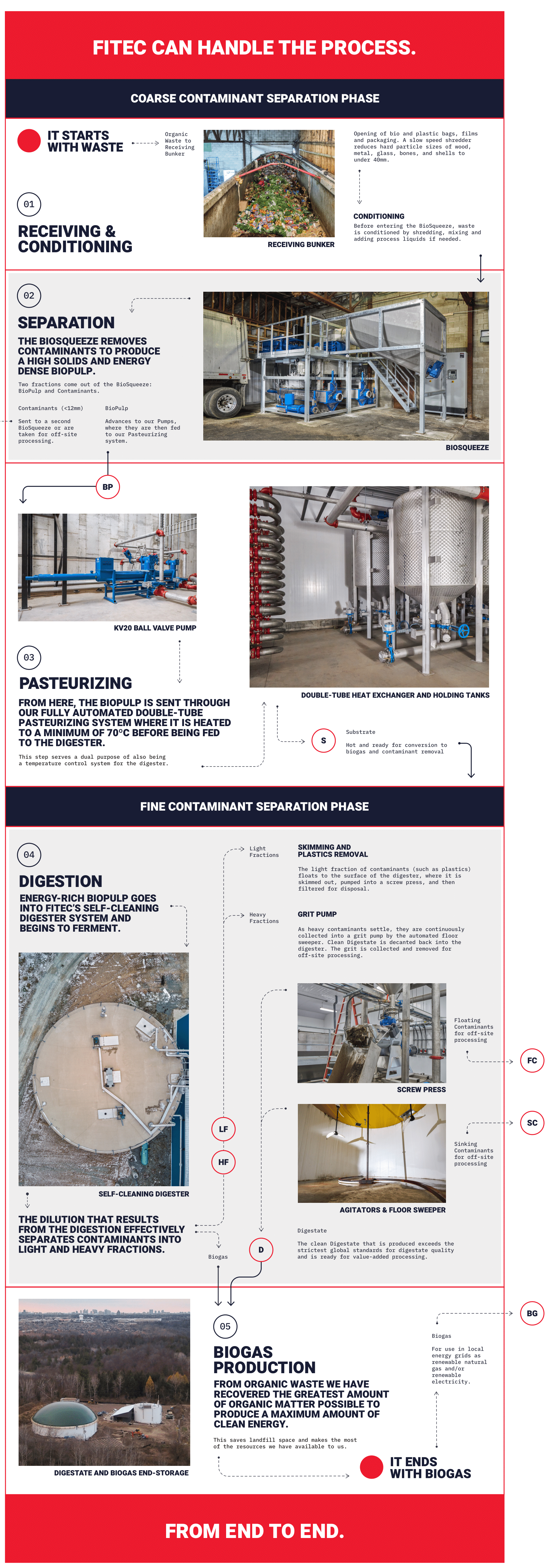

We specialize in the design and engineering of self-cleaning digesters in North America. Our systems allow for the treatment of industrial, commercial and institutional food waste (IC&I), packaged and expired foods, organic waste from single and multi-family dwellings, source-separated organics (SSO) and manure from livestock.

Our systems ensure the efficient separation of non-digestible fractions of organic waste, including sand, both during pretreatment as well as in the process. Reference projects in Ontario and Nova Scotia verify the high efficiency of our process and components. Our special components are tested and manufactured at our own commercially operated biogas plant in Germany.

We are able to help with all stages of building a plant, from planning and design to project management and construction supervision. We will oversee the provision and installation of our system components, including our custom-made automation technology, provide support during commissioning and operational support thereafter to ensure the optimal functioning of our system.

Products & Equipment

Our resource-efficient and automated biogas systems provide minimal downtime and maximum flexibility.

- Depackaging and contaminant separation

- Pasteurizing systems

- In-vessel plastics separation and removal

- In-vessel grit separation and removal

- Instantaneous digester health monitoring

- And more!

Services & Consulting

We look at systems from an operational standpoint and are well-equipped to understand your needs.

- Custom trace element formulation, manufacturing, and supply

- Biological health monitoring

- Feedstock analysis

- Biological system simulations

- Dynamic biomethane potential calculations

- And more!

We welcome any conversation about our products or services and would be happy to discuss your particular situation. Find our contact information on the sidebar or at fitec.ca.

You can also download our brochure to know more about us and our services:

Services

- Equipment suppliers

- Biogas System Engineering

- Biogas System Consulting

- Construction Services

Products

-

Fitec Self-cleaning digester

Fitec’s self-cleaning digester includes a grit removal system and a plastics removal system. Contaminants are continuously discharged to maintain maximum digester capacity…

View More -

Fitec BioSqueeze 200 Separation Press

The BioSqueeze 200, a signature piece of Fitec equipment, is a hydraulically operated press that separates waste into digestible and non-digestible fractions…

View More -

Fitec Pasteurizing System

The Fitec Pasteurizing System is designed to pasteurize organics with a high total solids content and a high level of residual contaminants,…

View More -

Fitec Pumps

Fitec KV Ball Valve and KP Gate Valve pumps are reliable and efficient with highly abrasive, high-solids, contaminated organic waste.

View More -

Fitec Handheld Bicarbonate Analyzer

A portable tool that allows operators to maximize biogas output and reduce incidents of overfeeding and system collapse.

View More -

Fitec Automated Bicarbonate Analyzer

An automated tool that allows operators to maximize biogas output and reduce incidents of overfeeding and system collapse.

View More -

Fitec Skimming and Plastics Removal

The Fitec Skimming and Plastics Removal System continuously removes floating contaminants such as plastics from the surface of the digester using a…

View More

Related News

-

04

22

Managing Food Waste Contaminants For High-Quality Biogas, Clean Digestate & Low Opex

Anaerobic digestion (AD) has become increasingly reliable in North America over the past 15 years, turning organics into clean energy and nutrients for the soil instead of contributing to greenhouse gas emissions. However, many biogas projects have also failed to...

Read More -

Press Release02

14

Fitec Lands Contract to Build World’s First Avocado Biogas Facility

Mexico-based Villa Avocado will digest the waste from their avocado oil production facility to close the loop and create renewable energy. Toronto, ON: Fitec Environmental Technologies Inc., a Canadian biogas design and engineering company, has signed a contract to build...

Read More -

Press Release03

12

FITEC, A CANADIAN BIOGAS COMPANY, LAUNCHES NEW WEBSITE FEATURING RECENTLY COMPLETED PROJECTS

Fitec Environmental Technologies Inc has launched a new company website where visitors can learn more about the biogas process and be introduced to some of Fitec’s most recent partners and projects. The new site features photography, videography, and technical specifications...

Read More