Product Suppliers

Service Providers

Projects & Bids

News & Events

Tools & Resources

RNG Forum 2025

Wangen BIO-MIX

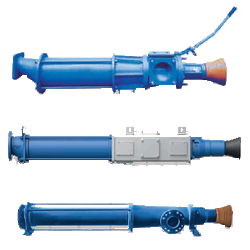

Pumps from WANGEN PUMPEN are highly regarded at regional, national and international level thanks to our consistent orientation to market and customer requirements. It is this high esteem in which we are held by our customers that motivates us to preserve, improve and breathe new life into our values day after day.

Contact Wangen America Inc.

Related products

Mixing and Dosing Feeder

The ONIXline Rotary Lobe Pump

The BLUEline Rotary Lobe Pump

BioGas Technology

Pumps

Agriculture Technology

Grinders and Macerators

Fitec Pumps

NEMO® Progressing Cavity Pump