Memthane

Veolia helps communities and industry ensure energy and water reliability, meet regulatory requirements and safeguard public health, all while protecting our natural resources. We introduce renewable energy sources and alternative fuels into the energy mix where it is viable.

Files

Product Description

Veolia’s Memthane: State-of-the-art Solution

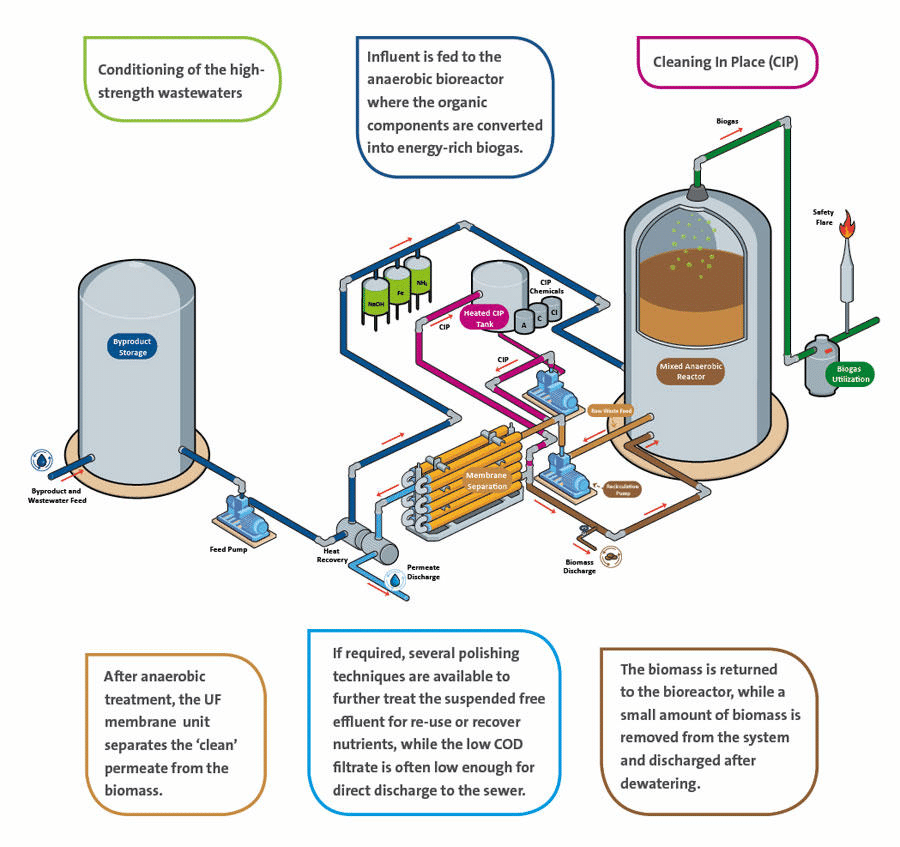

Memthane® is an Anaerobic Membrane Bio-Reactor (AnMBR) which maximizes renewable energy production while producing superb quality effluent that can be reused or discharged directly to sewer.

The new leading-edge technology, developed by Veolia Water Technologies’ subsidiary Biothane, delivers a unique, small footprint solution that offers an array of benefits, reducing disposal costs while generating valuable biogas.

Replacing fossil fuels by generating biogas from wastewater treatment.

Economical and easy to operate

In addition to its performance advantages, Memthane® delivers a significant total operating costs reduction compared to conventional technologies, taking into account all elements, including membranes, chemicals, sludge disposal and overall energy savings. The simple, single, fully automated reactor system offers the possibility of remote control.

Sustainable and profitable

Memthane® opens the door to treatment of high-strength and high-solid streams found in industries like distilleries, dairies, bio-ethanol producers, instant coffee plants, etc.

The suspended free effluent also facilitates easy recovery of nutrients for fertilizer production and water recycling to the plant.

The valuable methane-rich biogas produced can cover a significant part of the production plant’s energy and heat demand, which can be as high as 100% in distilleries, for example.

Due to the favorable investment and operating with robustness, clients are increasingly choosing Memthane® as their preferred wastewater treatment solution.

Memthane® treats high-strength effluents previously considered untreatable.

Memthane®, the perfect solution for:

- High concentrated streams

> COD 15,000 ~ 250,000 ppm such as Dairies whey

- Ethanol Facilities

> Stillage type streams: Pot Ale, Spent Wash, Thin Stillage and Vinasse

- Fat Oil and Grease (FOG) containing streams

> Ice cream and Biodiesel

- Starch slurries

- High COD chemical applications

2 proven technologies:

- Anaerobic biological treatment + Membrane separation = 1 innovative solution

- Maximizes COD + TSS removal,

- Eliminates disposal costs

- Generates methane-rich biogas

FEATURES AND BENEFITS

A world of advantages

- Reduces costs

- Superb effluent quality

- Maximizes green biogas energy

- Robust and easy to operate

- Easy recovery of nutrients for reuse

- Reduces carbon footprint

- Proven track record

- Avoids biogas scouring

- Odour free

- Easily scalable to meet individual plant characteristics and operating environments.

A proven process