Risks and safety measures for anaerobic digestion: How can you make your plant safer?

UPDATED: 2020/12/18

Safety Precautions for Anaerobic Digestion Systems

Whether you are designing, constructing or operating a biogas plant, you need to identify health and safety risks and plan measures accordingly to either eliminate or mitigate them to make your facility as safe as possible. It is a crucial step to avoid injuries and deaths.

Frequently, however, human errors, equipment breakdowns or equipment misuse are the causes of accidents. Thus, accidents are often avoidable if you anticipate the risks or you plan rigorously your project.

The summary below identifies the major hazards associated with an AD facility, presents some necessary safety measures, shows schemas of an AD facility and gives a few examples of past accidents that occurred in the industry.

Biogas

The biogas produced by an anaerobic digestion plant is composed of combustible gases methane (50-75%), carbon dioxide (25-50%), water (H2O), nitrogen (N2), oxygen (O2), hydrogen sulfide (H2S), ammonia (NH3), and trace elements (organo-halogenated, siloxanes, etc.). H2S, CO2, and water make the biogas very corrosive.

The composition can vary according to the nature of the incoming substrates and the operating conditions.

Properties of biogas

Source: Institut National de l’Environnement Industriel et des Risques (INERIS) – Translated

Biogas composition based on its source

Source: Institut National de l’Environnement Industriel et des Risques (INERIS) – Translated

Source: Institut National de l’Environnement Industriel et des Risques (INERIS) – Translated

Health & safety risks associated with a biogas plant

All the following risks are easily mitigated if health & safety are taken into account at all phases of a biogas project development. The risks include, for example:

- Fire and explosion

- Confined space hazards

- Risk of Asphyxiation

- Risk of gas poisoning (H2S, NH3)

- Risk of high-pressure gas or liquid leaks

- Risks associated with rotating mechanical equipment

- Risks associated with pathogens (diseases)

Fire and explosion

Under certain conditions, biogas in combination with air can form an explosive gas mixture. The risk of fire and explosion is particularly high close to digesters and gas reservoirs. It can occur because of a gas leak, creation of an explosive zone, welding, clogged or frozen pipes or others.

To generate an explosive atmosphere, the following conditions are met simultaneously:

- Presence of a combustible gas: methane (CH4)

- Presence of an oxidant: oxygen from the air

- Presence of an ignition source

- Concentration of the combustible gas included in its explosive range (LIE-LSE)

- Presence of a confinement.

Explosion triangle for biogas

Source: German Biogas Association

For a biogas composed of 60% methane and 40% carbon dioxide, the range of biogas concentrations in the air necessary to reach the explosive range is between 8.5 and 20.7.

Risk of asphyxiation

Biogas generation, transportation and flaring can lead to oxygen-deficient atmospheres. The biogas accumulation in a confined space can significantly reduce the level of oxygen (anoxia) and result in poisoning or asphyxiation symptoms, even death.

The minimum regulatory oxygen content is 19%. The asphyxiants that are typical constituents of biogas are carbon dioxide (CO2) and methane (CH4).

Chemical hazards

Due to their toxicological properties, ammonia, hydrogen sulphide or carbon dioxide expose operators to safety hazards. To reduce the risks, it is essential to maintain the threshold limit value (TLV).

Someone that is exposed to H2S concentrations of over 50 parts per million can get serious injuries or die. Such concentrations also cause pipes or steel tanks corrosion or breakdowns of the biogas engine.

Occupational exposure limit values (OELs) of the main hazardous gases in biogas

Source : Institut National de Recherche et de Sécurité (INRS) – Translated

High-pressure gas or liquid leaks

High-pressure gas or liquid leaks occur when pressure goes lower or high than normal in tanks. For example, a tank breakdown can cause a flooding of digestate on site. The digestate spreads on nearby lands if the flood is not contained on time.

Biological hazards (pathogens)

Wastes of animal and human origin, used as AD feedstock, contain various pathogenic bacteria, parasites and viruses. Pathogenic species that are regularly present in animal manures, slurries and household waste are bacteria (e.g. Salmonellae, Enterobacter, Clostridiae, Listeria), parasites (e.g. Ascaris, Trichostrangylidae, Coccidae), viruses and fungi.

For example, a tank spilling into a slurry tank can create projections and aerosols containing microorganisms.

Overview of hazards in biogas plants

Source: German Biogas Association

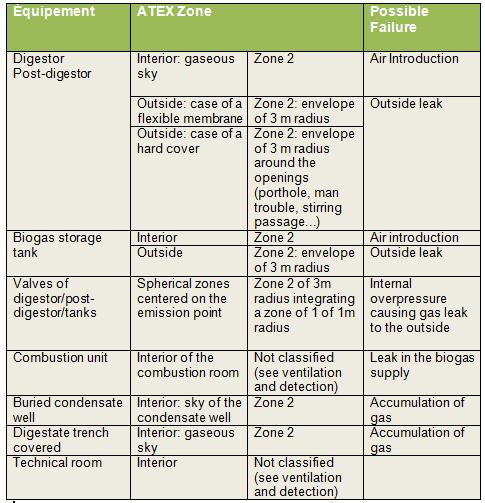

Zones at risks of explosion

Source : Institut National de l’Environnement Industriel et des Risques (INERIS) – Translated

Safety precautions

General

- Use corrosion-resistant material to water or sulphur products

- Equipment should be designed not to let biogas in or out

- Electrical installations must comply with standards and regulations

Regarding the fire hazards:

- The constituent materials, in particular digesters or the combustion unit, must be non-combustible

- The installations must comply with the provisions of Article R4216 of the Labor Code: provide specific extinguishing systems inside the premises of the detection systems.

- Storage inside the premises must be avoided

- Petrolium products storage should respect the Decree as of July 1, 2014 setting up the technical rules and applicable security for storage of petroleum products

Digesters, post-digesters and biogas storage tanks

- Install a device to protect against risks of explosion

- Safety valve: digesters and biogas storage tanks must be equipped with safety devices (safety valves) that prevent excessive vacuum or overpressure

- Sluice gates: have 2 sluice gates for one digester in the case one of them breaks down. Moreover, there should be a possibility to lock one of the sluice gates manually

- Mixer: get a backup power supply.

Biogas desulphurization through the injection of air

- Inside the digester or post-digester, air metering pump should be set so that the air flow does not exceed 8% of biogas volume produced at the same period

- Digester inlet piping should be equipped with a check valve that will prevent the biogas from flowing back.

Flares

The flares are necessary in risk control on a biogas plant. If there are problems or the plant is on start-up phase, the flares have to treat the biogas. The biogas cannot be sent in the atmosphere.

- Gas flares must be equipped with a flame arrester

- It must have a ventilation device

Condenser

- Make sure that during steam dump no biogas leaks outside

- Install detectors of high and low levels connected to the pump stop

Digestate storage tank

- If the tank is covered, it is important to ensure that it is sufficiently ventilated

- Install the detector of high level connected to the digestate supply.

Technical premises

Technical premises should be sufficiently ventilated.

Piping

Separate biogas and substrate piping. Biogas piping should be as well:

- Airtight and tested before first use

- Fluid, pressure and corrosion resistant

- Easily accessible and preferably placed on the surface

- Should consist of welded sections and not to go out of confined spaces, especially the premises

- Provide the slopes to evacuate the corrosive and condensate

- Piping holding the substate should be protected against freezing

- Security valves should be placed upstream of the installations intended for production, storage, treatment and use of biogas

- Systems that trigger security valves should be installed in easy-to-access places

How to minimize risks and ensure safety during every step of your biogas project?

The operator and the plant designer have to take certain measures at every step of a project. The goal is to ensure safety and minimize risks.

Plant design

This step is particularly important to ensure the safety of the biogas plant. The operator and the plant designer have to pay attention to:

- The norms, guidelines and all other codes that apply to biogas plants

- The classification of explosion zones, since the electric system installed on the biogas must be suited according to the risks of explosion

- Avoiding confined space

- Potential risks that can happen during the operation of the plant

Project construction

- Make sure to plan the project rigorously

- Hire an onsite expert to insure the workers apply the health and safety measures that are established

Biogas plant commissioning

Commissioning of a biogas plant can be the most dangerous step of a project.

Accidents that can happen include:

- Structural failure rarely happens when the tank is being filled or the high-pressure pipes are being tested

- Accidental hydraulic discharge during the pre-operation test of the pumps and valves

- Lack of calibration of the health and safety equipment

- Higher risks of explosion when the air inlets are opened and the air reach biogas

Biogas plant operation

During this step, a lot of accidents and incidents happen. To avoid them, the operator must:

- Train every operator of the plant for the work in confined space, portable gas detection, process and equipment use

- Apply strict procedures for equipment locking

- Regularly verify health and safety equipment to make sure they are calibrated and offer precise measurements

- Do a visual screening of all equipment to detect leaks and verify the state of equipment

- Make sure all workers apply health measures to avoid pathogen diseases

- Train all plant workers for basic firefighting skills and CPR

Examples of past accidents on biogas plants

In Europe, there were about 800 accidents on biogas plants between 2005 and 2015. Fortunately, less than a dozen of them had consequences on humans. Here are some examples.

Farm plant, Saint-Fargeau, France

In 2018, an explosion followed by a fire occurred at the level of the gasometer in the post-digestor of the farm plant in Saint-Fargeau, France. The accident happens during the initial test for the operation of the agitator when its propeller was replaced.

Consequences

- Breakdown of the gasometer

- Melting of the power cable of the agitators

- Sealing damage of the head veil

Causes

- Error made during the installation of the agitator

- Supporting system of the agitator is not connected to the ground

- Electric arc during the power interruption of the agitator, an ignition and flames source

- Non-efficient monitoring from certified organizations during the initial and periodic visits

Biogas plant of Rhadereistedt, Germany

In 2005, a large quantity of H2S leaks in the charging hall of the biogas plant of Rhadereistedt, Germany. The workers don’t follow the procedure to discharge the truck because of a breakdown of the lid covering the tank. The tank containing animal and dairy waste is left opened.

Consequences

- Death of the truck driver and of 3 other workers

- Injuries and hospitalization of another worker

Actions taken

- Apply safety measures to avoid the operation of the agitators when the lid of the tank is left opened

- Make new streams to avoid sending liquid digestate through the trench

- Optimize ventilation system

- Install gas detectors

- Avoid intermediate storage in the trench during the nights and weekends

- Avoid mixing materials

- Train workers

Complementary guidelines about risks and safety measures on anaerobic digestion plants

There is a number of guidelines on required safety measures for an anaerobic digestion plants. You can read them to get more information on this topic.

The document Safety rules for agricultural biogas plants (l’Institut national de l’environnement industriel et des risques de la France) (In French only) include information about the operation and maintenance of a biogas plant. It contains critical measures to prevent risks during the operation, reception, starting, testing and maintenance of biogas plants, to intervene in confined spaces, in the digestors, post-digestors and storage tanks.

Depending on your region, here are a few guides that you might find useful:

- United States: Safety Practices for On-Farm Anaerobic Digestion Systems (EPA)

- Germany: Safety Rules for Biogas Systems (German Agricultural Occupational Health and Safety Agency) and Biogas: Safety First (German Biogas Association)

- Quebec: Lignes directrices pour l’encadrement des activités de biométhanisation (Gouvernement of Quebec) (In French only)

Need more information?

Biogasworld is your go-to information resource in the industry of biogas and biomethane/RNG. Our team has the profound knowledge of the market that allows us to share the most relevant data on strategically important topics.

Our library of resources includes topics such as risks and safety precautions on biogas plants. Download a sneak peek of our report that is specifically about safety measures here.