A new partnership between Sebigas and Headworks International: the Anaerobic MBBR reactor

Olgiate Olona, Italy and Houston, Texas 12 October 2022 – Partnership takes Headworks Internationals’ innovative EnergyCell™ anaerobic Moving Bed BioFilm Reactor (MBBR) to increase renewable energy production and OPEX savings for industrial wastewater treatment.

A technological proposal for International markets is now available thanks to the partnership between Sebigas, a company specializing in biogas with more than 80 plants worldwide, and Headworks International, a US company with over 30 years of experience specializing in wastewater treatment technologies for industrial and municipal effluent treatment using MBBR/IFAS and a pioneer in the Patented AnMBBR process.

This highly engineered technology allows industries such as dairies, breweries, paper mills, sugar refineries, distilleries, and slaughterhouses to convert their wastewater treatment plants into assets by utilizing their discharged wastewater to capture renewable energy. Additionally, anaerobic treatment has significant advantages over its aerobic counterpart beside the production of usable energy in the form of biogas. AnMBBR has lower energy demands, a smaller footprint, and less sludge production.

Siva Angappan (Director, Process Engineering & Technology – Headworks) Afnan Din (Vice President & Process Manager – Headworks) Somnath Basu (VP Global Process Engineering – Headworks) Paolo Ruffino (Process Biologist – Sebigas) Gerald Seidl (Senior Vice President – Headworks)

For example, a medium-sized dairy, which produces 100 m3/day of wastewater containing whey, treated with the new anaerobic MBBR reactor, would produce:

- 90-120 Nm3/h of biogas

- 200÷250 kWh of electrical and thermal energy, for an annual production of 2 million kWh.

The Sebigas and Headworks partnership aims to provide sustainable solutions for industrial wastewater treatment. Through their partnership, both the companies will further expand their business opportunities and their network in the international markets.

“We are proud to announce our partnership with Headworks, a company with a great experience, established and recognised not only in the American market, but also worldwide” – says Roberto Salmaso, Sebigas General Manager. “This partnership establishes an important step that allow us to extend the products and services offered to a sector whose potential is extremely high. Furthermore, by decoupling from the incentive logic in favour of energy efficiency in industrial processes, we provide an immediate benefit to sectors particularly affected by rising energy prices.

“At Headworks International, our team continues to focus on offering innovative, sustainable solutions to the water sector. Energy prices are soaring. Climate change impacts on the availability of water are accelerating. One piece of the puzzle of lowering industrial energy costs and complying with CO2 reduction requirements is reframing our view of wastewater as an asset to be converted to energy,” says Michele LaNoue, Headworks’ CEO. “These are exciting yet challenging times for our industry and this partnership allows us to combine our expertise with Sebigas and jointly offer solutions to provide immediate tangible benefits to the industrial sector.

How does the anaerobic reactor MBBR work?

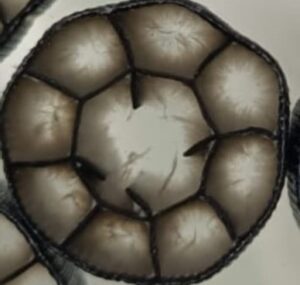

The collaboration between Sebigas and Headworks includes Headworks’ EnergyCell Anaerobic MBBR for new wastewater management systems or the retrofitting of existing treatment plants. The treatment of industrial wastewater in anaerobic digestion takes place with the insertion into the reactor of “media carriers,” virgin plastic elements whose shape is characterised by a large, protected surface area. Left in suspension, they act as a support for the proliferation of bacteria: the concentrated biofilm created on the surfaces of the carrier allows the bacteria to digest the organic load in the effluent more efficiently.

What are the benefits of choosing the EnergyCell Anaerobic MBBR reactor?

A company that chooses Anaerobic MBBR technology pursues a path of circularity, achieving clear benefits not only economically, but also environmentally. In fact, industrial waste is not only not ‘thrown away’ but is exploited to produce additional energy, which is fed back into the company.

From an engineering point of view, it is an ideal solution for treating high volumes of wastewater in a plant, optimising space compared to other treatment systems, which require much larger surfaces. A sustainable alternative that reduces the organic load in industrial wastewater; the production of energy from biogas becomes a key energy carrier and a sustainable alternative for self-consumption of electricity and heat.

Lower energy demand and lower costs make AnMBBR technology an opportunity and a chance for many companies.

“The AnMBBR reactor represents an efficient and effective solution for transforming the organic load from various industrial wastewater into biogas – says Federico Torretta, Project and Product Manager at Sebigas. “It is a much more resilient system than other reactors, easy to operate, capable of absorbing variations and shock loads in the treated wastewater. Its small footprint makes it an attractive choice for both new installations and existing treatment plant retrofits.”

About Sebigas

Sebigas is an engineering company active since 2008 and specialised in the design, construction and management of biogas and biomethane plants worldwide. With a portfolio of more than 80 plants built on 3 continents, and an installed capacity from 200 kW to 3 MW, Sebigas plants registers 98.2% availability at maximum power, equivalent to approximately 8,600 hours of operation per year with plant down time kept to a minimum. Sebigas is a reliable partner with consolidated experience in the treatment of heterogeneous biomasses, able to supply tailor-made plants, designed around the client’s needs to guarantee optimal and continuous operating efficiency. From its headquarters in Italy, Sebigas operates worldwide, supported and sustained by its membership since 2020 of the international TICA group, with approximately 3000 employees, 10 production plants worldwide and 70 Branch offices.

About Headworks International

Headworks International Inc. is a leading engineering and manufacturing company supplying biological wastewater systems and liquid/solid separation equipment to the worldwide municipal and industrial wastewater treatment industry. From its innovative MS Bar Screens; its efficient plant upgrades with its proprietary MBBR/IFAS processes; to its unique, small footprint HIT biological treatment systems, Headworks is your answer. The biological division focuses on providing proven highly efficient technologies for treating wastewater for reuse while doubling your flow capacity within existing tanks or reactors and meeting tight effluent discharge limits. Its proprietary range of bio carriers coupled with our market expertise allows our team to design with the optimal specific protected surface area. These carriers, with a design life of over 20 years, are deployed in aerobic reactors like MBBR/IFAS, as well as in its Energy Cell Anaerobic MBBR.

Headworks International Inc. is headquartered in Houston, Texas, with offices in Canada and the Middle East. The men and women of Headworks come from many cultures, creating a rich mix of experiences and forming a unique understanding of the global marketplace.

To discover more: email us at sales@sebigas.com.