The objective of this handbook is to provide the reader with a general project development roadmap to assist him/her through the complex tasks of planning, designing, procuring, permitting, building and operating an efficient and viable biogas plant.

Note that this handbook will be regularly updated with new content about biogas, anaerobic digestion, and the best practices of our industry.

Biogas plant development handbook sections

Foreword

Our firm has been selling biogas engineering expertise for over 12 years in various agricultural, agro-food and municipal organic waste management sectors. I’m constantly amazed to discover that significant biogas plant projects suffer from improper planning and design resulting in suboptimal biogas plants operation and economics. Most of these easily avoidable errors are due to initial misconception, lack of knowledge and information on the subject of biogas plant engineering.

There exist a lot of excellent publications on the subject of anaerobic digestion and biogas utilization but very few on the subject of biogas engineering and biogas project development as a whole.

I remember my early years as a biogas engineer where I got infatuated with the subject and devoured a large quantity of technical information on anaerobic digestion and biogas utilization. Over the years, these technical aspects have receded to the background as I focused my work on equally complex issues such as project planning, financing, procurement, permitting, politics and operation. It is these subject matters that are the primary focus of this handbook.

This handbook has been written to be published as either a set of ever-evolving hyperlinked articles in a website (BiogasWorld) or as a standalone eBook because the rapidly evolving biogas industry demands it.

I hope you will enjoy the reading and find valuable information to help you design, build, and operate a better biogas plant.

Eric Camirand, P.Eng.

President, Electrigaz Technologies Inc.

1. Introduction

This handbook has been written for readers recognizing themselves in one of these statements:

-

- You are asking yourself how you could turn organic waste into gold?

-

- You have been tasked with the job of building a biogas plant to treat organic waste and have no clue how to go about it?

-

- You have been studying this subject for years and you think you are now ready to build your own biogas plant?

-

- You are intrigued by this amazing technology converting waste into renewable energy and fertilizer and want to learn more about it?

-

- You have been learning about biogas for years and the more you learn about it, the more you realize its complexity and get confused?

- You are operating a biogas plant and are wondering why it is performing poorly and trying to find concrete solutions to these problems?

If you identified yourself in one of these statements, you are officially deemed cursed with an infinite appetite for more information on the subject matter of biogas plant development and operation.

This handbook has been written to help you make the best out of your predicament.

2. Why building biogas plants?

Why would you not want to get rich by turning organic waste into renewable energy and fertilizer while reducing overall environmental issues related to their disposal?

In reality, there exist three (3) reasons why people build biogas plants:

-

- Compliance with regulation

-

- Economic opportunities

-

- Madness

Beyond this reality, there exists a killer question that is frequently asked: “Why not compost? Isn’t it less expensive?”

The easy answer is: “It depends.” (not a very useful one, though). In reality, it is difficult to answer this question simply. Each project has its own regulatory, energy market and local environmental realities that influence the choice between composting or anaerobic digestion.

In general, it is cheaper to perform open air composting at smaller solid organic waste tonnages (less than 10 000 tonnes/year). Beyond that, a thorough feasibility study must be performed to measure the challenges and opportunities of each organic waste treatment technology.

Anaerobic digestion and composting often played one against the other. In reality, these technologies are complementary and should often be developed jointly to leverage the strengths that each has to offer.

Regulatory

There are three (3) major regulatory drivers forcing the development of biogas plants:

- Greenhouse gas (GHG) policies

- Renewable energy policies

- Recycling policies

Despite their biogas capture systems, landfill emits a significant amount of fugitive methane to the atmosphere, therefore contributing to greenhouse gas emissions. Additionally, landfilling of organics does not comply with typical recycling policies that state that waste should be reduced, reused and recycled (3Rs) prior to final disposal, since organic waste in this scenario is not returned to land.

For these reasons, GHG and recycling policies are generally leading to the ban of organic landfilling therefore forcing composting and/or anaerobic digestion of organic waste.

Renewable energy policies, such as Renewable Portfolio Standards (RPS), established in many states and countries force energy utilities to produce a certain percentage of their energy from renewable sources. These utilities are constantly on the lookout for affordable renewable energy such as biogas energy.

Economic opportunity

Biogas plants create economic opportunities in markets where energy costs and/or waste disposal costs are relatively high. Since the organic fraction of municipal solid waste can represent approximately 50% of MSW mass, it becomes economically interesting to divert the organic fraction from conventional disposal towards anaerobic digestion.

Processing of organic waste in a biogas plant can help reduce waste disposal cost. Production of biogas from organic waste can help generate an affordable renewable energy. Combined, these opportunities drive the development of biogas projects.

For example, small island countries can benefit greatly from biogas plant since they often generate expensive and dirty electricity with diesel ($0.50+/kWh) and are confronted with significant challenges regarding disposal of their waste.

Madness

Some biogas plants get built for no good reasons, primarily driven by sheer madness and/or egotistical motivations. Most of these project developers were blind to key biogas project fundamentals that will be discussed later in this handbook.

These poorly planned and executed projects are resulting in biogas plants with poor operational and economic efficiencies and, in general, hurt the industry.

3. Anaerobic digestion

Anaerobic digestion is a natural bacterial process by which a consortium of anaerobic bacteria is biodegrading organic matter in an environment without oxygen.

These bacteria require a favorable environment to thrive. Proper temperature, lack of oxygen, proper feeding, acidity, and mixing are the key to efficient anaerobic digestion.

The anaerobic digestion process takes place in equipment called anaerobic digesters or, in short, digesters. Digesters must be fed as constantly as possible regardless of feedstock fluctuations.

Several types of bacteria work together to convert the digestible volatile solids within the feedstock into biogas. Though most feedstocks are composed primarily of water, you cannot make biogas with water. You make biogas out of the digestible fraction of the solids within the feedstock.

Although lignocellulosic material, such as wood, contains a lot of volatile solids (burnable), these solids are not digestible in an anaerobic digester.

The conversion of solids into biogas makes the substrate more liquid. That’s why it is possible to feed solid feedstock into liquid digesters without them clogging up.

Biogas is composed primarily of methane and carbon dioxide.

4. Biogas Plant Fundamentals

Inexperienced biogas developers often focus their effort on the technical aspects rather than the project fundamentals.

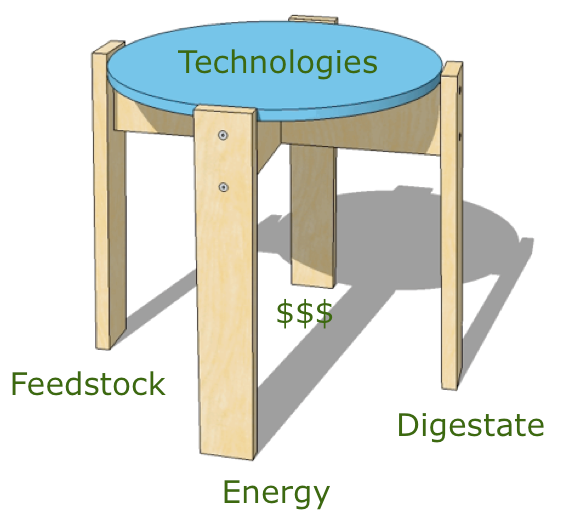

The technology choice is always secondary to the establishment of the following fundamentals:

The feedstock quantity and composition must be well known and under the control of the project developer. Without proper feedstock, there is no biogas project.

There must be a client for the biogas energy. If there is none, you might as well just compost the material.

Biogas plants transform only 10% of the mass they process into biogas. The remaining 90% of the mass fed into the digester comes out as a fertilizer called digestate. The project must have a long term inexpensive outlet for this digestate otherwise the project will not succeed.

Finally, the project must be bankable. That means that investment, operational costs, and revenue must be predictable and balanced for the project to secure its financing.

If any of these fundamentals fall short the table will tilt and will make the project viability difficult or impossible. The technology choice is a result of these fundamentals.

5. Biogas plant Health & Safety

Like any other industrial activity, biogas plant accidents happen, and people get hurt or die. Not only do these accidents hurt people, but they also set back the biogas industry as a whole. It is important that biogas plant health and safety becomes an integral value of all biogas plant designers, builders or operators, as well as the general public. Obviously, plant designers and operators must work hand in hand to identify health and safety risks and take actions to mitigate them.

Biogas plants are often perceived as dangerous infrastructures because they feature impressive reservoirs containing biogas. In general, the public wrongly fears explosions because it is assumed that these reservoirs are entirely filled with pressurized explosive gases when in fact they are filled primarily with wastewater with only the top of the tank containing near atmospheric pressure biogas.

Health & Safety Risks Associated with a Biogas Plant

All the following risks are easily mitigated if health & safety are engraved within all phases of a biogas project development:

- Fire

- Explosion

- Confined space hazards

- Gas poisoning (H2S, NH3)

- Hydraulic discharge

- High pressure gas or liquid leaks

- Rotating mechanical equipment

- Pathogens (diseases)

- Electrical system hazards

Design Phase Health & Safety

The design phase is crucial to overall biogas plant safety. The first line of defense comes from the various norms and codes that are there to protect public health and safety. By following established codes such as CSA, NFPA, OSHA, Building codes, etc., the designer ensures that the plant is safe for its operators.

Proper explosion zone classification is essential to ensure that the electrical system installed is adapted to the explosion risk. In general, biogas piping and equipment is kept outside of the buildings to avoid costly explosion-proof equipment and buildings.

The creation of confined space should be avoided as much as possible during the design phase to ensure a safe and easy-to-operate environment for the workers. It goes along that proper ventilation must be designed to ensure health and comfort of the biogas plant operators.

Furthermore, operational activities need to be understood at the design phase to identify various risks that may arise from operations. Risk analysis such as “what if” and HAZOP need to be performed to identify, quantify, and find risks mitigation strategies.

Construction Phase Health & Safety

As any other industrial construction, biogas plant construction requires proper planning and on-site measures to ensure the health and safety of the workers building the plant.

An on-site health and safety agent is often required to ensure respect of established health and safety measures.

Commissioning Phase Health & Safety

For various reasons, the commissioning of a biogas plant is probably the most dangerous phase of a biogas plant project life.

Since methane is explosive in air at a concentration between 5% and 15%, the digesters contain an explosive atmosphere at some point during the start-up phase. When methane concentration rises above 15%, the risk of explosion is considerably reduced. In fact, biogas plants are then more likely to catch fire than to explode.

Although rare, structural failures may occur during system loadings such as reservoir filling or high-pressure piping testing.

Accidental hydraulic discharges may occur during pre-operation testing of pumps and valves, which may cause injuries.

It is important to test and calibrate health & safety equipment to ensure that they are ready for service during the most dangerous phase of the project.

Operation Phase Health & Safety

Incidents and accidents occur mainly during the operation of the plant, and they are either caused by equipment failure, improper equipment utilization, or plain human errors.

The most deadly accidents are caused by gas poisoning (H2S and NH3) in open and confined spaces.

Proper confined space training and portable gas detection should be mandatory for all biogas plant operators.

Equipment lockout procedures should be strictly enforced to avoid unnecessary accidents. Proper training on processes and equipment should be mandatory for all biogas plant operators.

Health and safety equipment, such as gas detection, should be routinely checked for precision and calibration.

Proper hygienic procedures (showers, hands cleaning, etc.) need to be enforced to avoid pathogen-driven diseases.

Finally, the staff of a biogas plant should be trained in basic firefighting skills and able to practice CPR.

Click here to see US EPA common safety practices for On-Farm AD systems Common Safety Practices→

6. Input feedstock

The feedstock dictates the biogas technology to be used, not the other way around. In order to properly design a biogas plant, the developer must fully understand its feedstock.

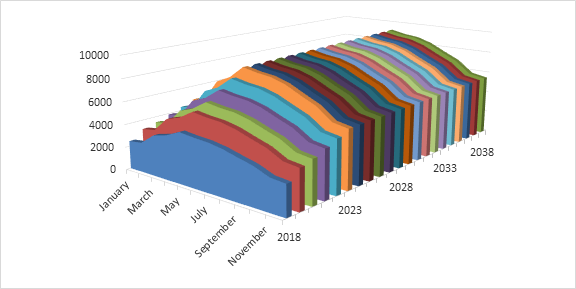

How will the feedstock be collected and arrive at the biogas plant? How much of it? When will it come? Which form, liquid or solid? Which type of trucks? Is there a significant variation in volumes throughout the seasons? Will this volume increase or decrease over the years?

A significant amount of work must go into trying to model the variation of feedstock throughout the days, months and years of a project. Without this information, it is likely to lead to improper sizing of biogas plants resulting in an inefficient operation and investment.

The composition of the feedstock must also be well known to identify the most suitable technologies to process this material. Furthermore, understanding feedstock composition will allow forecasting digestate quality which will help identify outlets for the digestate.

A detailed analysis of the feedstock composition from a trusted laboratory will outline the following feedstock properties:

- Dry matter content or total solids (TS)

- Volatile solids (VS)

- Total Kedjhal Nitrogen (TKN)

- pH

- Alkalinity

- Contaminants (plastics, glass, metals, etc.)

The total solids test consists of completely drying the material to determine the mass ratio of solids versus the water in the material. For example, dairy cow slurry typically contains 10% solids and 90% water.

The volatile solids test consists of burning (600 °C) the solids from the total solids test to determine the mass ratio of volatile solids (burned) versus ashes.

Note that lignocellulosic material (wood) and plastics will volatilize but are, in fact, not digestible by anaerobic digesters.

Furthermore, anaerobic digestion may be hindered by various inhibiting compounds such as sulfur, salts, ammonia, etc.

For these reasons, additional tests may be performed on the feedstock to determine digestibility, long-term stability and biogas yield. Laboratories with biogas expertise will offer the following tests:

- Biomethane Potential (BMP)

- Anaerobic Toxicity Assay (ATA)

- Continuous Digestion

7. Biogas process technologies

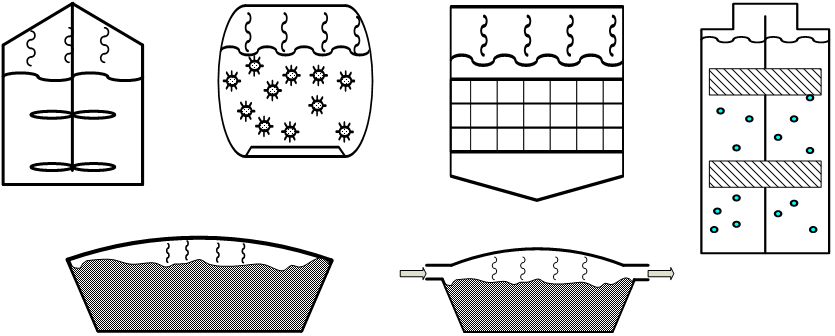

Anaerobic digestion processing technologies are divided into two major families:

- Wet digestion

- Dry digestion

In either case, these technologies offer either batch or continuous processes.

Wet digestion

The process is considered wet digestion when the content of the digester is pumpable. That means that the material inside the digester has a consistency of approximately 10% dry matter or less (90% water).

There exist many configurations of wet digesters:

- Complete mix or Completely stirred tank reactor (CSTR)

- Plug-flow

- Upflow Anaerobic Sludge Blanket (UASB)

- Fixed film reactor

- Floating films reactors

- Sludge bed reactors

- And more.

These configurations have been designed to optimize the process for various feedstock conditions and market applications.

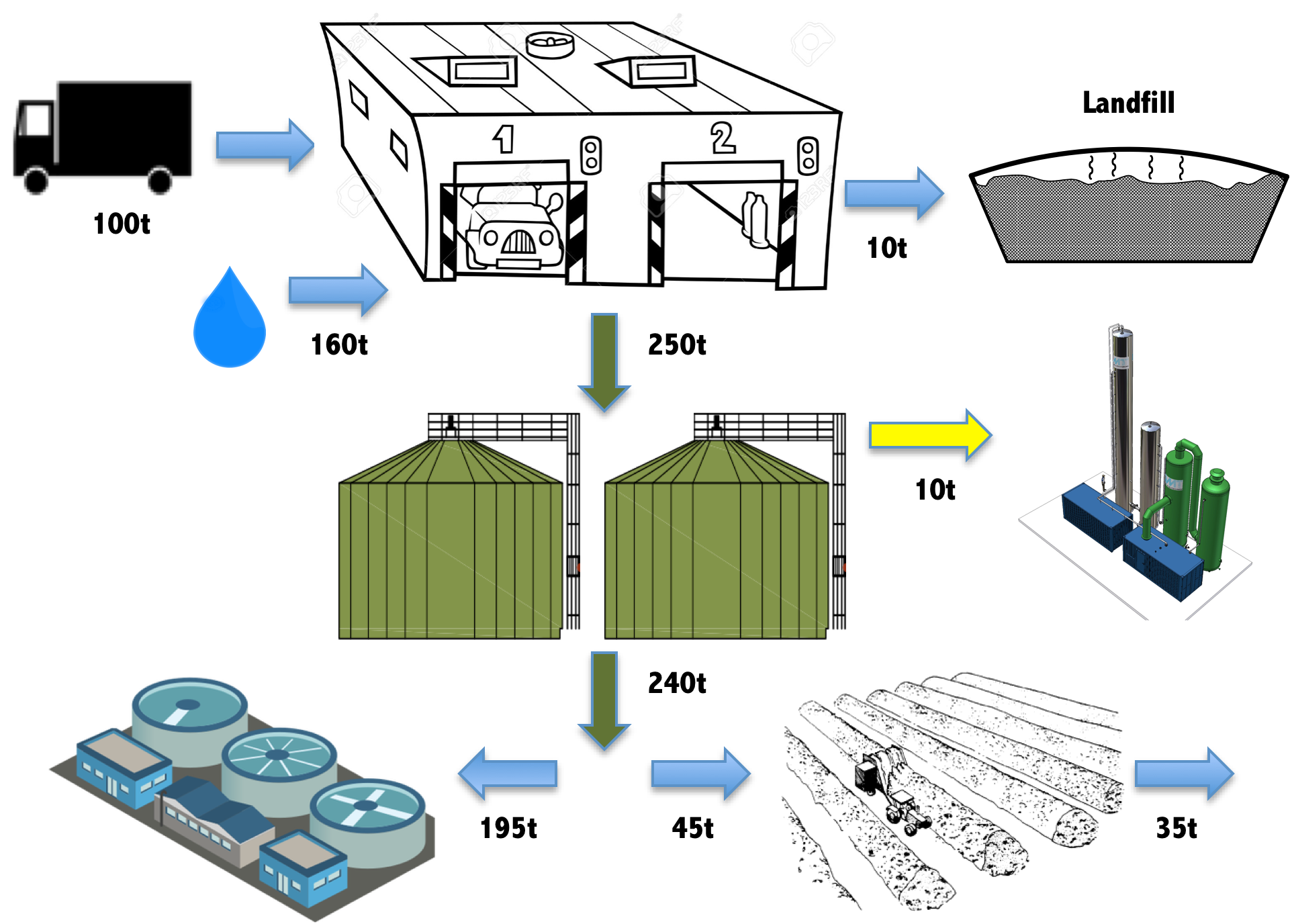

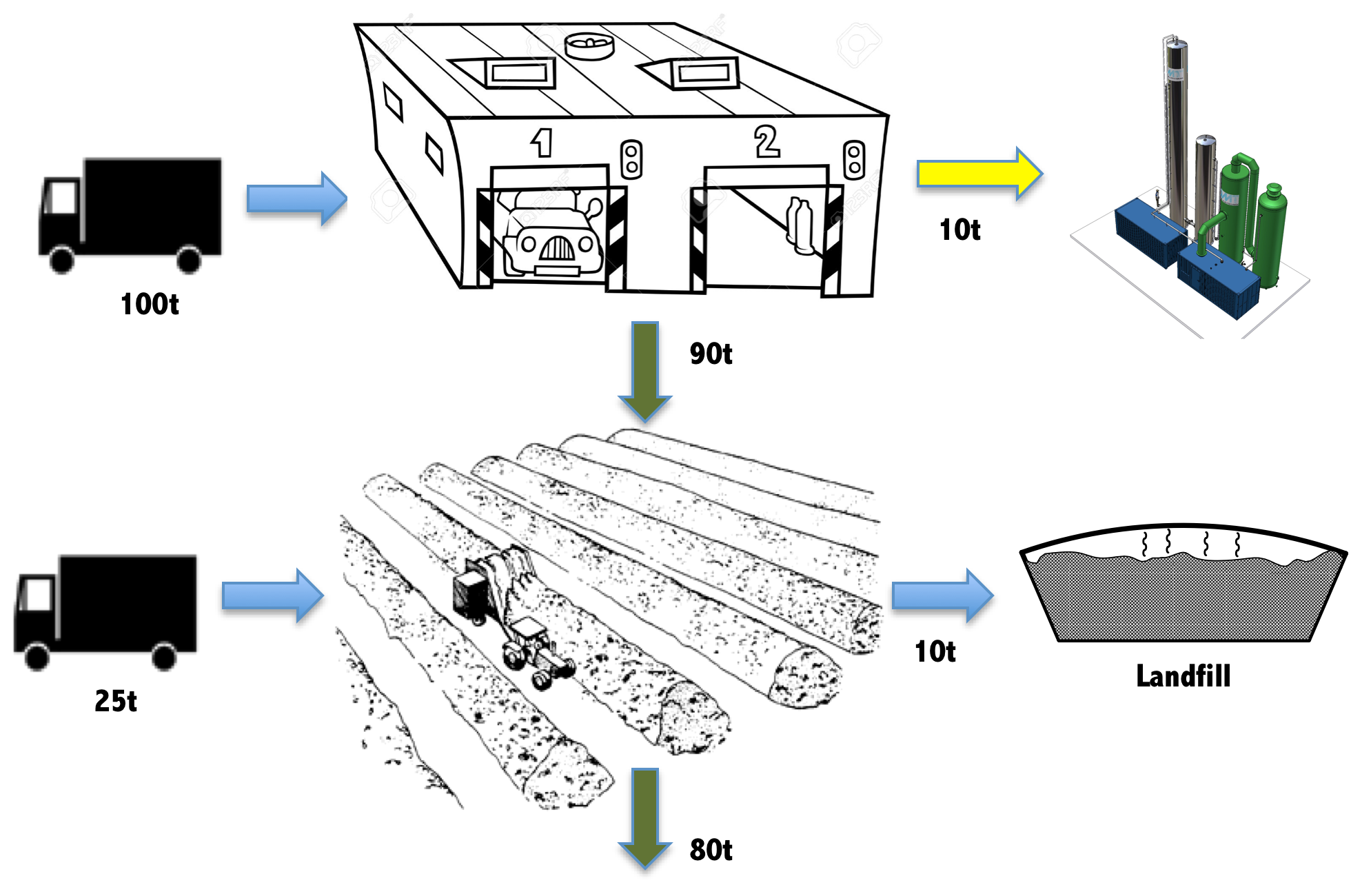

The mass balance of a typical wet digestion process looks like this:

For example, 100 tonnes of solid municipal residential source separated organics (SSO) arrives at the biogas plant using wet digestion (complete mix). This feedstock needs to be pretreated to remove potential contaminants (plastics, metal, sands, etc.). Approximately 10 tonnes will be removed as contaminants and will probably be landfilled.

In order to be pumpable (10% TS), the feedstock will be diluted with water that may come from a fresh source or from a mixed of fresh and recycled water from the wastewater portion of the biogas plant. The liquid feedstock going to the digester will be approximately 250 tonnes.

In the digesters, the bacteria will consume the majority of the volatile solids in the feedstock and will convert them into biogas. Approximately 10 tonnes of gas will come out of the digesters. The more liquid digestate will represent approximately 240 tonnes.

At this point, the digestate may be applied to land directly. Please note that 100 tonnes of solid material turned into 240 tonnes of liquid and land applying the digestate in this form will present significant transportation costs.

The digestate may also be separated into a solid fraction (45 tonnes) to be land applied (or composted down to 35 tonnes) and a liquid fraction (195 tonnes) to be returned the sanitary sewage or directly back to nature.

One may be tempted to use the treated wastewater as dilution water for the input feedstock and limit the amount of water consumed and rejected by the process. It is possible only if the wastewater plant removes almost all nutrients (salts and ammonia/ammonium) in the water. Without this removal, there will be a rapid build up of nutrients in the water and this will inhibit and/or kill the anaerobic digestion process.

Dry digestion

The process is considered dry digestion when the content of the digester is not pumpable. That means that the material inside the digester has a consistency of approximately 10% dry matter or more.

There exist many configurations of dry digesters:

- Continuous vertical

- Continuous horizontal

- Batch (Garages)

- And more.

These configurations have been designed to optimize the process for various feedstock conditions and market applications.

The mass balance of a typical dry digestion process

For example, 100 tonnes of solid municipal residential source separated organics (SSO) arrives at biogas plant using dry digestion (garage style). This feedstock does not need to be pretreated to remove potential contaminants (plastics, metal, sands, etc.).

In the digesters, the bacteria will consume the majority of the volatile solids in the feedstock and will convert them into biogas. Approximately 10 tonnes of gas will come out of the digesters. The solid digestate will represent approximately 90 tonnes. Note that the digestate coming out will be more liquid than the incoming material. In some cases, it may be necessary to add some bulking agent prior to digestion to ensure the out outgoing material remains solid.

In certain continuous “dry” digesters the material can come out as a thick liquid. In these instances, this liquid is still contaminated with (plastics, metals, rock, sands, etc.) and is very difficult material to recycle to land.

In our example, the solid digestate cannot be applied to land directly because the contaminants have not yet been removed. In order to remove the contaminants, the material will have to be dried enough to allow sieving without clogging the screens.

The most efficient way to dry this material is to compost it with drier material such a garden waste. Compost is a science of its own and will not be discussed here. However, we will mention that composting often required a bulking agent (25 tonnes) to ensure proper material structure complying with aerobic composting conditions. The bulking agent will be added to the tonnage of material to be sieved to achieve recycle to land quality.

The digestate may also be separated into a solid fraction (45 tonnes) to be land applied, and a liquid fraction (195 tonnes) to be returned the sanitary sewage or directly back to nature.

Here also, one may be tempted to use the treated wastewater as dilution water for the input feedstock and limit the amount of water consumed and rejected by the process. As with wet digestion, it is possible only if the wastewater plant removes almost all nutrients (salts and ammonia/ammonium) in the water. Without this removal, there will be a rapid build up of nutrients in the water and this will inhibit and/or kill the anaerobic digestion process.

Wet versus Dry digestion

As illustrated in the examples above, there is no silver bullet, and it is not true that dry digestion resolves all wastewater issues since composting plants have leachate treatment challenges of their own.

In the example above, using the wet digestion process resulted in 100 tonnes of SSO being converted into 45 tonnes of solid digestate and approximately 100 tonnes of wastewater (some recycled). The result of dry digestion process is 80 tonnes of compost recycled to land prosessed within a composting plant of equal size to the biogas plant.

In general, it is possible to remove ammonia from the wastewater the wet digestion is favored, and if the composting is possible the dry digestion is used.

8. Biogas energy

Biogas is a versatile renewable energy that can be used into direct thermal, electrical and to displace natural gas in thermal or vehicular applications.

Biogas is generated biologically from renewable biomass. Therefore, it is carbon neutral. By displacing fossil fuels with biogas energy, biogas projects achieve greenhouse gas (GHG) emissions reductions that are the cornerstone of worldwide climate change mitigation strategies.

Biogas from properly functioning anaerobic digestion system is typically composed of:

- Methane (55-65%)

- Carbon dioxide (35-45%)

- H2S (100-10000 PPM)

- Water vapor (saturated at biogas temperature)

- Ammonia (traces)

Like biogas, natural gas is composed primarily of methane. Biogas is like wet natural gas diluted with carbon dioxide and other corrosive gases. Biogas from landfills will have less methane in proportion because air (nitrogen & oxygen) gets inhaled into the biogas collection system.

Biogas utilization

Each biogas application requires specific biogas conditioning and conversion equipment.

Renewable Natural Gas (RNG) or Biomethane

There exist several technologies that allow for cleaning or upgrading the biogas into a renewable natural gas of quality suitable for injection into the gas grid.

These technologies are:

- Water wash

- Membranes

- Adsorption or PSA

- Absorption or Organic solvent dilution

- Others

These technologies allow the removal of carbon dioxide (CO2) and other impurities (H2O, N2, H2S, siloxanes, etc.) so that that the biomethane becomes interchangeable with conventional natural gas and can be injected safely into gas pipelines. Typically, these technologies will capture approximately 90+% of the methane in the biogas (loss of 10% of less) and will bring biomethane or renewable natural gas quality to 97+% CH4.

Click here to read more on Renewable Natural Gas→

Combined Heat & Power (CHP)

In this application biogas is cleaned up to remove primarily H2S, siloxanes, and water vapor prior to being fed into an internal combustion engine (ICE) or a micro-turbine. The engine or turbine turns an electrical generator producing electricity that is injected into the electrical grid via a set of electrical protections and transformers.

In the process, the engine generates a lot of heat. Heat recovery units are added to the engine to recover exhaust gas heat and engine cooling heat to generate hot water or low-pressure steam.

Typically, a biogas CHP will convert 40% of the biogas energy into electricity, and 50% into hot water.

CHP has a typical capacity factor of 95% which means that they produce electricity steadily throughout the year (8300+ hrs/yr) making them a reliable energy production asset.

Direct thermal (boiler or furnace)

In this application, biogas may be cleaned or not (depending on H2S or siloxanes) and fed into a boiler to make hot water or steam for industrial applications. Boiler efficiency can be as high as 95%, so almost all the biogas energy gets converted into useful energy (hot water, steam or hot air).

However, natural gas equipment must be converted in order to burn biogas efficiently since biogas has less energy because it contains 40% CO2, which is not a fuel.

Note that a boiler connected to a biogas plant will produce heat 24/7 and will require a heat client with similar energy profile needs, otherwise the energy will be wasted.

Natural Gas Vehicles (NGV) applications

Natural gas vehicles exist in all sizes and shapes such as passenger cars, SUV, pickups, minivans, buses as well as light, medium and heavy-duty trucks. Currently, NGVs are not overly popular in the Americas but they are quite common in Europe and Asia. Several vehicles OEMs offer natural gas models.

Natural gas vehicles are internal combustion engine (diesel or gasoline) vehicles that are fuelled with natural gas that is stored in either high-pressure cylinders in a gaseous form (CNG: compressed natural gas) or in cryogenic tanks in a liquid form (LNG: liquefied natural gas).

There are two (2) types of natural gas engines: diesel or gas engines.

Diesel engines are modified to replace the majority of the fuel consumed with natural gas. In such modified diesel engine, the diesel is necessary to ignite the natural gas since it will not auto-ignite under pressure like diesel does.

Gas engines are essentially gasoline engines modified to burn natural gas. Natural gas is injected (like gasoline) in a proper air-to-fuel ratio to provide the right explosive mix for used in the piston.

Typically, natural gas engines (diesel or gas) are less fuel efficient (15%) than their gasoline or diesel equivalent.

There also exist dual-fuel systems that allow the user to run on either fuel or both at the same time. In the case of diesel engines, one could run on diesel only on a mixture of natural gas and diesel in different proportion depending on load. In the case of a gas engine, typically the engine can run on either gasoline or natural gas.

These dual-fuel systems are typically used to extend vehicle range and offer flexibility by allowing the use of the vehicle in regions where natural gas stations are not available.

In Canada, because it is allowed to carry heavier loads, that is why a lot of heavy-duty transportation is performed with 15-liter diesel engines (typically 500 HP). Currently, there are no 15-liter OEM heavy-duty natural gas trucks. Most heavy-duty natural gas trucks revolve around a 12-liter Cummins gas engine (400 HP).

Biogas or Natural Gas as a Fuel

Biogas cannot be used directly in compressed natural gas vehicles. Because of its corrosive components, biogas will compromise the safety of the high-pressure cylinders. Likewise, biogas cannot be liquefied without removing its H2S, CO2 and H2O otherwise it will corrode or ice up (wet and dry ice) the liquefaction process.

However, if biogas is converted to renewable natural gas (RNG) or biomethane as described above, it can thereafter be used interchangeably with natural gas to fill up natural gas vehicles.

Typically the biogas plant will inject its biomethane or RNG into the grid and the NGV station will be built somewhere along the grid. In this scenario, the grid acts as a buffer because the filling cycles are unlikely to match the steady production of a biogas plant.

Natural gas vehicles offer a 25% reduction in GHG emissions over the same application in diesel.

By using RNG or biomethane we can reduce by over 90% the GHG emissions in transportation applications.

CNG vs LNG

Liquefied natural gas (LNG) is natural gas that has been cooled down to -160°C at which point it changes phases to liquefied and uses 600 times less volume.

LNG offers more energy density at 22 MJ per liter than compressed natural gas (CNG) at 9 MJ per liter @ 3600 psig. For this reason, LNG is often used for applications that require a longer range of operation like heavy-duty trucks. In comparison, diesel energy density is 36 MJ/liter.

CNG is used for all type of transportation applications but offers a shorter range of operation.

All natural gas engines use the natural gas in gaseous form at relatively low pressure.

In the case of CNG, the pressure is downgraded via a pressure regulator. Depressurizing the gas will cause it to cool substantially, that’s why it is paramount that the natural gas is very dry prior to compression to avoid icing during decompression in the vehicle fuel system.

In the case of LNG, liquefied natural gas stored in a cryogenic tank (essentially a thermos) is pumped into a vaporizer that will heat the liquefied natural gas above its boiling point (-160C) where it will turn into gas and will be fed to the engine. When the vehicle is not used the liquefied natural gas will start to boil off when the temperature in the tank goes above -160C. The boil-off is gaseous natural gas that will build pressure into the cryogenic tank (approx 100 psig). A pressure release valve will open and vent the excess gas to the atmosphere. So, LNG vehicles cannot be stored inside. Moreover, LNG vehicles should not stand still for a long period of time, otherwise, they will vent their fuel to the atmosphere and generate greenhouse gases. CNG vehicles do not have this venting/fuel losses issue.

Both technologies, CNG and LNG, have their pros and cons and the choice really depends on the application.

Nevertheless, the CNG technology is more readily adopted than LNG because of its simplicity and availability of fuel (LNG production is complex and far apart).

Natural Gas Stations

There exist three (3) types of NGV stations: LNG, CNG time-fill, and CNG fast-fill.

LNG stations are essentially composed of cryogenic tanks, pumps, dispensers and cooling systems. LNG is brought from the production plant to the station with tankers and transferred into the station cryogenic tank. The cryogenic tank is kept cool using various techniques (e.g., liquid nitrogen) to avoid boil-off of the fuel. Fuelling vehicles pull up to the dispenser and connect a hose to the cryogenic tank on the vehicles and start pumping. Displaced gaseous natural gas filling the tank is recovered by the same nozzle and sent into the station tank to ensure no venting of natural gas to the atmosphere.

CNG time-fill stations are stations that fill up the vehicles over a long period of time (ex. overnight). These stations are composed of a gas dryer, a high-power compressor, and several dispensing hoses upon which the vehicles are connected to be filled over a long period of time (10 hours) allowing for cooling of the cylinders over time as well as a truly complete fill.

CNG fast-fill stations are stations that allow for a quick fill up the vehicle equivalent to their diesel or gasoline counterparts. These stations are composed of a gas dryer, a high power compressor, high-pressure buffer cylinders (4500 psig), dispensing valves and dispensers similar to gasoline or diesel types. The vehicles pull up to the dispenser and connect the high-pressure hose to their vehicle cylinders and start filling. Initially, the pressure from the high-pressure buffer cylinders will start the fill up without the compressor and as the pressure between the station and the vehicle equilibrates the compressor will kick in to complete the fill.

As you fill up a cylinder quickly the pressure and temperature will rise. When the maximum pressure is reached (i.e., 4000 psig) the compressor will stop. But has the cylinder cools down, it will lose pressure and may settle down to 3600 psig (10% less than rated tankage).

NGV Economics

NGV vehicles cost more money than their equivalent counterpart in diesel and gasoline.

In either technology, CNG or LNG, most of the additional cost comes from the onboard storage tanks (high-pressure cylinders or cryogenic tanks).

Natural gas on the grid is abundant and cheap ($5-8/GJ). Diesel is highly fluctuating but in general significantly more expensive ($25-35/GJ).

The compression or liquefaction of the natural gas to make it NGV usable will cost an additional $5-10/GJ. Therefore, natural gas ready for NGV consumption will cost approximately $12-20/GJ after station operator’s profit. The higher end of this range will represent the cost of LNG and the lower end a large volume CNG time-fill station.

So, it appears that NGV should cost 50% less to operate than diesel or gasoline equivalent.

In reality, the additional cost of the vehicle, modifications to the garage to make it suitable for natural gas vehicle maintenance (explosion issues), incomplete fills, natural gas engine lesser efficiency all reduce this saving to approximately 25 to 30%.

So why isn’t there more NGV on the roads?

There are several factors that slow down the deployment of NGV’s, such as:

- Lack of knowledge

- Resistance to changes

- Refuelling anxiety (vehicle range)

- Lack of NGV fuelling stations

- Limited OEM vehicles offer

- NGV price tags

- Fluctuation of diesel price

- Etc.

There is a chicken and egg issue (stations Vs vehicles) that government with interest in biogas and/or natural gas production/distribution development and GHG reduction should resolve by providing incentives to build more stations and buy more vehicles until the industry gathers a critical mass.

Click here to use our CNG fleet savings calculator→

Biogas production versus consumption

Stable anaerobic digestion process will produce biogas steadily 24 hours per day, 365 days per year without any interruption.

The biogas energy clients must have a similar consumption profile or must provide a buffering capacity to absorb the differences between the production and consumption.

Biogas storage

Biogas is typically stored at near atmospheric pressure. Since biogas in its raw form is wet and corrosive, it cannot be stored in pressure vessels because it will cause corrosion leading to safety issues.

Pressure storage is possible only if the biogas has been upgraded to renewable natural gas pipeline specifications.

Storage at atmospheric pressure takes up a significant volume.

9. Digestate management

As illustrated in the section about Wet Versus Dry Digestion, there are essentially five (5) types of digestate:

- Clean liquid digestate

- Clean solid digestate

- Contaminated liquid digestate

- Contaminated solid digestate

- Contaminated semi-solid digestate

Only the clean liquid or solid digestates can be directly applied to land without further treatment. These digestates often originate from manure, food waste or pre-treated SSO digesters where there are virtually no contaminants in the feedstock to be digested.

Most of the time, liquid digestate is separated into solid and liquid fractions by using liquid/solid separation technologies.

Solid fraction

As mentioned earlier, clean solid digestate can be applied to land directly.

Contaminated solids coming from a dry digester or a liquid/solid separation equipment will need to be composted to achieve proper dryness for the sieving of contaminants prior to land application.

Liquid fraction

Also mentioned earlier, clean liquid digestate can be applied to land directly.

Contaminated liquids coming from a wet digester or a liquid/solid separation equipment will require proper wastewater treatment such as sedimentation of suspended solids, abatement of COD, BOD and ammonia compounds.

10. Biogas plant components

Site

Several aspects need to be studied in the choice of a site:

- Dominant wind/Air dispersion

- Road access

- Proximity to energy grids

- Geotechnical

- Contamination

- Proximity of neighbors

Civil work

The biogas plant will be equipped with roads, scale, drainage, landscaping, etc.

Buildings

Biogas plants will have one or more building(s) to contain the process and all the human resources operating and maintaining it. These building may require special architectural specifications for aesthetic, comfort and efficiency.

Reception

This is the area of the biogas plant where the feedstock is received. It may be designed to receive several trucks of various sizes. Typically, the reception of material will be indoor, and this is where most of the odor challenges arise. Opening and closing of doors for trucks is typically the main source of odors for a biogas plant.

Feedstock conditioning

Depending on the technology used, this is where the received material is prepared for feeding into digesters. It may be decontaminated by using technologies such as:

- Hydro-pulpers

- Separating hammermills

- Presses

Anaerobic digestion

Central equipment of a biogas plant, the digester is where feedstock is biodegraded by anaerobic bacterias to generate the biogas and digestate.

Digestate treatment

Separation : The liquid digestate may be squeezed to separate the liquid fraction from the solids.

Composting : A biogas plant may be equipped with a composting plant to stabilize or allow the drying and decontamination of the solid fraction of its digestate.

Wastewater treatment: The liquid fraction of the digestate often needs to be treated prior to disposal into nature or into sewage.

Odour treatment

Odors generated inside the building need to be controlled (with proper ventilation) and treated prior to rejection into the atmosphere.

Biogas handling

The following list includes all the equipment necessary to handle the biogas:

- Pipes

- Flowmeters

- Condensate traps

- Storage

- Flare

Biogas treatment

Equipment necessary to clean the biogas to the proper specifications for the intended application.

Biogas utilization

Equipment that will allow utilization of the biogas or biomethane (RNG) as follows:

- Boiler

- CHP

- Biogas upgrader

- Compressor

11. Biogas project economics

Biogas plant economics are complex and vary with local market conditions.

Revenue

Biogas plants can generate several revenues such as:

- Treatment fees: Money you receive (or save) for accepting and treating the feedstock. In North America, this represents the majority of the income of the project (60-80%).

- Energy sales: Money you receive for selling the biogas energy (20-40% of income). Only in markets with generous feed-in-tariffs will the energy sales constitute the majority of the project income.

- Digestate/compost sales: Money you receive (or save) for selling your digestate or compost. Typically, you have to pay to dispose of the digestate or compost.

- Carbon credits: Biogas plants do generate carbon credits that can be sold. However, the volume is small, and the validation and certification fees often take the lion’s share of this income.

Financing

Biogas plants are financed using equity, debt, subsidies and tax credits. Municipalities will finance their project with subsidies and debt. Private projects will require significant equity (25%) and energy contracts from solid clients to secure their debt.

OPEX

Operational expenses (OPEX) are typically composed of:

- Salaries

- Debt service charges

- Disposal charges (contaminants, digestate)

- Energy (consumed)

- Equipment maintenance

- Consumables

- Taxes

- Insurances

CAPEX

Capital expenses (CAPEX) vary greatly between projects.

Municipal projects are the most complex and expensive. Typically, in North America, they cost anywhere between $800-$1500/tonne of annual treatment capacity.

Agricultural projects are the simplest and least expensive. Typically, in North America, they cost anywhere between $4500-8000/kW electrical installed.

12. Biogas project development

There exist several critical steps in the realization of a successful biogas project, though project developers tend to focus their effort on determining the best anaerobic digestion technology for their project instead of getting a firm grip on their project fundamentals before anything else.

Biogas plants are large expensive finicky biological systems that require careful planning. In fact, most biogas plant failures are due to poor planning and/or not paying close enough attention to project fundamentals such as feedstock, energy utilization, digestate management, and financing.

Studies & Preliminary Engineering

A lot of work must be put into establishing the project fundamentals (studies).

Establishing expected feedstock collection methods (trucks, bins, routes, etc.), quantity, quality and overall logistics (collection contracts, transfer stations, hours of reception, etc.) often require significant studies and planning. One must not underestimate the effort necessary to understand how much, when, and in what state the organic waste will get to the biogas plant.

Finding a proper site for a biogas plant also requires significant effort. The site needs to meet proper zoning, and environmental regulations (proximity to houses, rivers, wells, etc.). The site must also be easily accessible by road for the feedstock to come in, and the digestate to come out without causing too much traffic nuisance to the neighborhood. Finally, the site must be close an energy grid (gas or electrical) in order for the biogas energy to be exported efficiently.

Digestate management must be studied carefully since the disposal of digestate is often the largest operational cost of a biogas plant. All possible avenues of disposal, transformation or treatment must be taken into consideration to ensure that the final strategy for digestate management is the most efficient. Otherwise, the biogas plant economics will be less than optimal.

Once the fundamentals are established, a concept will be drawn and priced to get a project budget.

Beyond this initial engineering concept, further studies and analysis are often required as follows:

- Site contamination (soil, buildings, etc.)

- Risks analysis

- Value analysis

- Applicable codes, rules and regulations

- Timeline estimation

Proper preliminary engineering is essential to develop a viable business case that will justify the significant financing required to realize the biogas project.

Design

Detailed engineering of a biogas project is composed of several disciplines working in close collaboration such as:

Project Management

To ensure that all engineering disciplines are working together closely to efficiently deliver an optimal design.

Process Engineering

To determine the processes required for feedstock conditioning, anaerobic digestion, gas treatment, digestate treatment, odor management, etc.

Mechanical Engineering

To deal with all aspect of material handling: solid waste reception & conveying, liquid pumping, gas compression, etc.

Electrical Engineering

To deal with all aspects of power supply and automation (sensors, PLCs and actuators).

Civil Engineering

To handle excavation, filling, and utility services (drainage, sewer, water, etc.).

Structural Engineering

To ensure foundations are safe and sound to support the structural load of the building bearing the process equipment.

Building Mechanical Engineering

To handle all aspects of ventilation, fire protection, lighting, non-process electricity and plumbing.

Architecture

To handle all technical and visual aspects of the site and buildings.

Detailed engineering is performed to generate drawings and establish specifications for all the components of the biogas plant. The design must obviously comply with local codes and regulations.

Permitting & Energy Contracting

Once the drawings and specifications are completed, the project must obtain all necessary permits for construction. Depending on the jurisdiction, there are usually several different authorizations required from local municipalities and environmental agencies.

In parallel, an energy contract should be negotiated with the local energy provider. These contracts can be technically and legally complex and will require proper technical and legal support.

Do not underestimate the time required to perform permitting and/or negotiate an energy contract with energy providers.

Financing

Financing will only occur if the project is permitted and if there is a serious client for the biogas energy.

Equity and guarantees will be demanded by financiers. Due diligence will be performed on the design, the clients, the management, risk analysis, etc.

Only upon satisfying all these answers will the project funding be confirmed.

Procurement

Purchasing the products and services to realize the design. Typically, the procurement of the plant will be broken down into several contracts, such as:

- Site decontamination

- Civil works

- Foundations/concrete work

- Quality control labs (materials)

- Building structure

- Building envelope

- Building mechanicals

- Electrical

- Automation

- Process equipment (digesters, gas upgrader, hydropulper, conveyors, etc.)

- Mechanical installation

- Construction management

- Engineering supervision

Public entities, such as a municipality, will often issue a request for proposals (RFP) for a design-build (DB) or a design-build-operate (DBO) so that all these procurement contracts are performed by the chosen contractor. Municipal procurement is often cumbersome and slow, thus one should expect significant potential delays in the realization of the biogas project.

Construction

Once all the permits are granted and the financing obtained, the procurement and construction can begin.

Proper construction management, supervised the general contractor, is essential to ensure that procurement and the execution of the various contracts are well timed to avoid construction conflicts and unnecessary delays.

Engineering supervision is necessary to ensure that the constructions are in accordance with the design.

Construction sites must be managed properly to ensure security and safety of the workforce. The site must be able to accommodate temporary services (electricity, sanitation, accommodations, etc.) as well as material and equipment reception (laydown) and storage.

Commissioning

Upon completion of the various phases of the biogas project, pre-operational verifications must be performed to ensure that all equipment was properly installed. At this point in time, a partial acceptance of the biogas plant can be granted so that the various contractors can get paid.

After verification, the anaerobic digestion process may be started. There must be a proper coordination with the feedstock collectors to ensure they can sufficiently and efficiently supply the process with the feedstock.

Upon achievement of the performance of the biogas plant, a final acceptance may be granted to pay the balance of suppliers and officially begin the operation of the biogas plant.

Operation

Day-to-day operation of the biogas plant includes the following tasks:

Reception of Material

Operators will coordinate the logistics of feedstock arrival, perform visual inspection of the received material, and log tonnages received.

Conditioning of Material

Operators will transfer the material from the reception to the conditioning equipment.

Anaerobic Digestion Process Control

Operators will operate and monitor the various aspects of the anaerobic digestion process, such as temperature, OLR, FOS/TAC, pH, etc.

Operation of Digestate Treatment System

Operators will attend to the dewatering, drying, and water treatment processes.

Operation of Wastewater Process

Operators will ensure that the water treatment process is functional.

Disposal of Contaminants

Operators will manage the logistics and disposal of all contaminants generated by the process.

Operation of Composting Process (if there is)

Operators will operate and monitor the various aspects of the composting process.

Disposal of Digestate/Compost

Operators will manage the disposal of the digestate/compost.

Maintenance

Biogas plants are equipped with multiple equipment that must be maintained to remain optimally functional throughout their entire planned life cycle.

Also, operators must establish and perform preventive maintenance on the equipment.

Unplanned maintenance and repairs are also to be expected and required daily.

Optimization

Optimization of the biogas plant may be achieved by performing modifications to improve processes or performance.

Afterword

Nowadays, online documents are constant work in progress that can be re-edited at a click of a button. In this new world, the concept of afterword is somehow obsolete. However, I would like to say that writing the first version of this handbook has procured me a lot of satisfaction and I hope I will derive the same feeling trying to make it progress over time to make it become a work of reference used by all getting on the trail to the development of a productive biogas plant.