Organics Extrusion Press OREX

Anaergia’s Organics Extrusion Press (OREXTM) reliably and efficiently separates solid waste streams into wet organic and dry fractions, driving significant value through both resource recovery and diversion.

Files

Product Description

Organics Extrusion Press OREX: Recovery from Solid Waste

Overview

The Organics Extrusion Press (OREX) reliably and efficiently separates a variety of waste streams into a wet organic fraction and a dry fraction, driving significant value through both resource recovery and diversion.

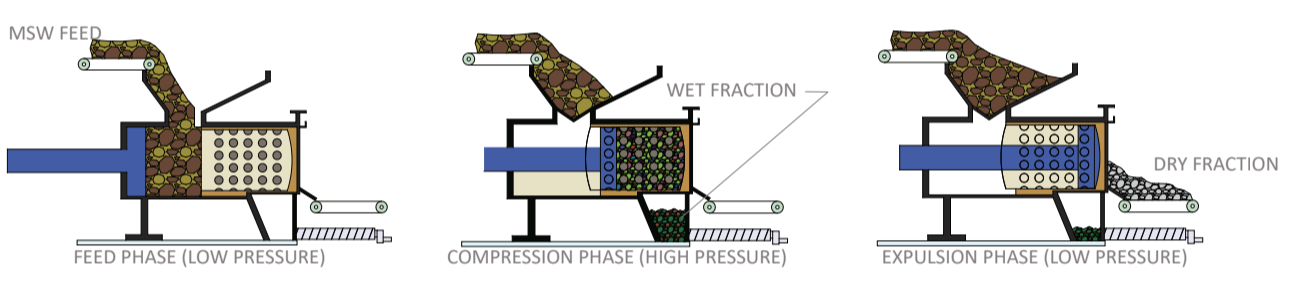

Process

An OREX processing line is a key component of an integrated solid waste program. The OREX physically seperates mixed solid waste into two components: wet and dry fractions. Unlike traditional screens, the OREX is capable of recovering up to 95% of food waste found in Municipal Solid Waste with < 1% contamination. Waste is fed into a perforated chamber, where it is compressed under high pressure (4,000 psi). The wet fraction of waste is squeezed through the perforations, making it available for anaerobic digestion. The separated dry fraction can be conveyed to a transfer pit or upgraded to a solid engineered fuel. The dry fraction has a lower moisture content, increased density when compared to the incoming solid waste, and increased energy value.

MSW Organics Recovery

Single Family Residential: 30-35%

Multi-Family Residential: 35-50%

Wet Commercial Waste: 50-70%

Source Separated Organics: 70-95%

System Advantages

• Minimizes need for customer behaviorial changes by relying on existing collection program.

• No source separation required, contaminated mixed waste streams are easily processed by the OREX

• A variety of waste streams can be processed (municipal solid waste, wet commercial waste, source

separated organics)