Bio Thelys

Veolia helps communities and industry ensure energy and water reliability, meet regulatory requirements and safeguard public health, all while protecting our natural resources. We introduce renewable energy sources and alternative fuels into the energy mix where it is viable.

In 2013, Veolia’s solutions prevented 24 million metric tons of global carbon emissions and converted 38 million metric tons of waste into new materials. At the same time, we produced 54 million megawatt hours of energy and provided water and wastewater management services at over 8,500 facilities around the globe.

Files

Product Description

Veolia’s Bio Thelys: A complete sludge reduction solutions

By coupling the thermal hydrolysis and the anaerobic digestion, Bio Thelys offers better performance than a conventional digestion and optimizes sludge treatment by producing:

- 25 to 35% less dry matter

- 30 to 50% more biogas

- No odours

- A pasteurised digestate, for full control over the sanitation hazards and safe agricultural reuse.

Bio Thelys handles all kinds of organic, industrial or municipal sludge and can also handle grease.

Using Bio Thelys process allows to:

- Reduce sludge volume

- Improve sludge quality

- Increase biogas production

Features and Benefits

Bio Thely is a flexible and safe solution which produces a pasteurised digestate that is compliant with international standards e.g.: EPA class A (UAS) and ADAS Safe Sludge Matrix (UK).

Bio Thelys allows:

- Reduced digester related investment for new installations

- Reduced operating costs:

- Less sludge to remove

- At existing installations, the digestion capacity can be increased by handling new input.

- An income which is generated from:

- Either processing external input through co-digestion

- Either selling the energy produced by co-generation or producing bio-methane

Bio Thelys is a solution that guarantees energy and environmental performance, thanks to:

- Conversion into “green” electricity via co-generation

- Bio-methane production (for injection into the network or as fuel)

- Complete sludge pasteurization

- Reduced carbon footprint of the facilities

- Many possibilities for using biogas: with external input (co-digestion), energy self- sufficiency or even a positive energy footprint may be achieved by the plant.

Bio Thelys combines with other Veolia sludge treatment processes such as Athos (hydrothermal oxidation), Pyrofluid (incineration), BioCon (thermal drying), Solia (solar drying) and completes them to offer even more sustainable solutions.

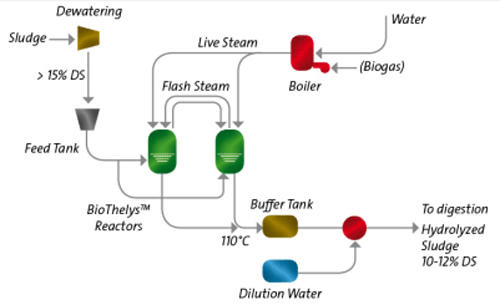

The Bio Thelys process

Dehydrated sludge first goes through a batch thermal hydrolysis phase during which steam is injected in reactors operating under specific pressure (9 bar) and temperature (165°C) conditions for approximately 30 minutes.

Visit the Website of Veolia to know more!