Sulfothane

Veolia helps communities and industry ensure energy and water reliability, meet regulatory requirements and safeguard public health, all while protecting our natural resources. We introduce renewable energy sources and alternative fuels into the energy mix where it is viable.

Files

Product Description

Veolia’s Sulfothane: remove the sulphur compounds in biogas

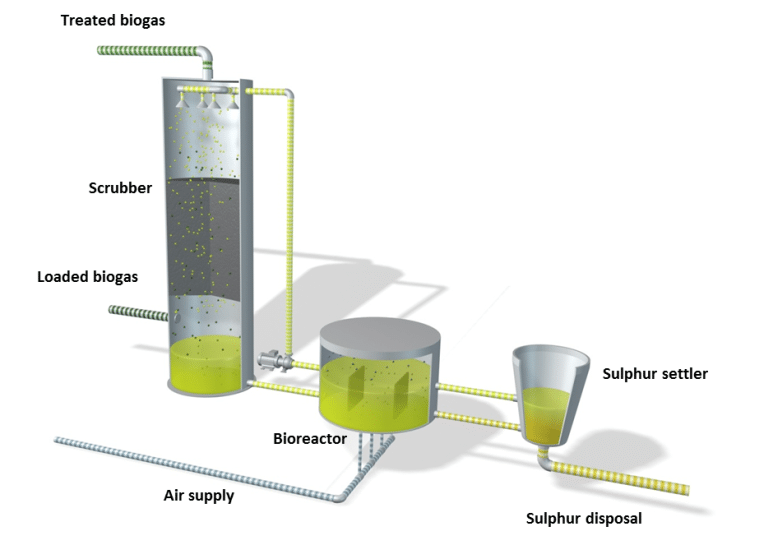

The Sulfothane Desulphurization Unit can be seen as a combination of an alkaline washing column combined with a biological production of elemental sulphur in combination with an alkalinity recovery step.

Why remove the sulphur in biogas?

Biogas is a valuable renewable energy source receiving ever more attention. Biogas can be generated by the anaerobic treatment of industrial wastewaters, by the digestion of manure and other bio-wastes, and is released as landfill gas from covered landfill sites.

Before the biogas can be utilized, it is essential to remove the sulphur compounds, which are mainly present in the biogas as sulphide (H2S). Sulphur can cause severe corrosion in boilers and engines utilizing biogas. Sulphur is an essential nutrient for living organisms, and is found for instance in proteins. During the production of biogas, the sulphur is converted biologically to H2S. Fortunately, biological processes can also be used to remove the H2S from the biogas.

Benefits of the Sulfothane process

- Deep H₂S removal efficiency

- No addition of air (N2, CO2 and O2) to biogas stream, therefore very suitable for further biogas upgrading without changing clean biogas flow and composition

- Small footprint

- Most reliable and robust H2S removal process, applicable to high turn down ratios and S-load fluctuations.

- Very fast and stable start-up procedure with small biomass inoculum

- Significant chemical savings (caustic, active carbon, iron ore) leading to much lower operating cost.

- No risk of clogging in the scrubber column

Process of the Sulfothane

The biogas is lead through a scrubber column where it is mixed and separated with wash water, removing H2S and some CO2 under alkaline conditions. No air (O2 and N2) will be added. Thus the composition of the biogas remains almost unchanged except for the removal of H2S.

In a second step the loaded wash water will enter a slightly aerated bioreactor where aerobic sulphur bacteria oxidize all H2S to produce elemental sulphur and recover alkalinity. The H2S free (unloaded) wash water will be returned and re-used in the scrubber. The separated sulphur sludge will be removed to further use or disposal.

For more information, visit the Website of Veolia!