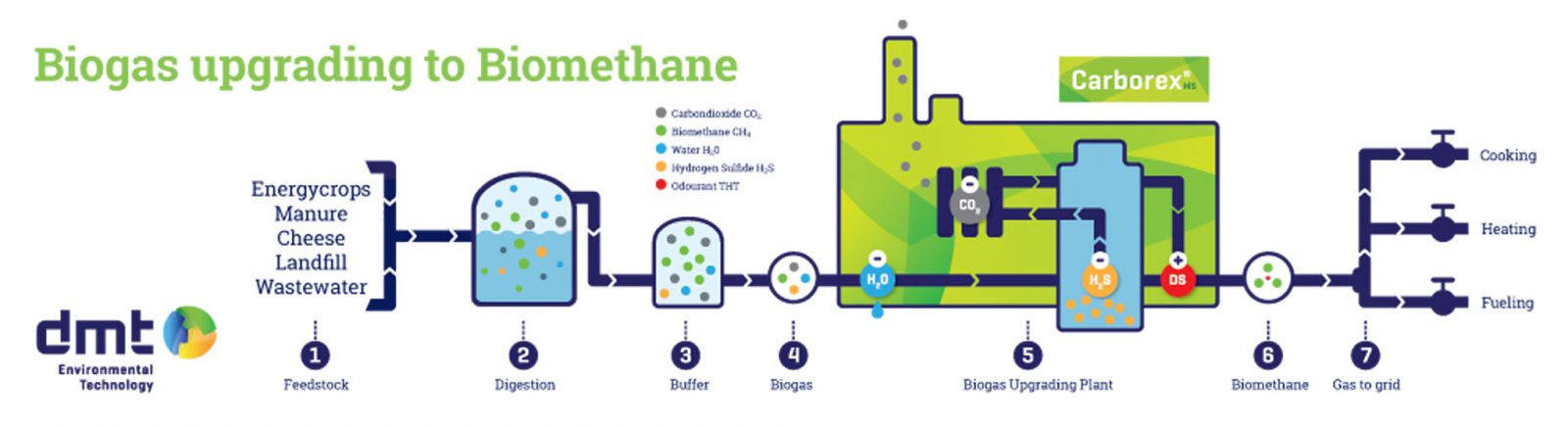

DMT Clear Gas Solutions – Carborex MS, biogas upgrading to biomethane

With a Carborex MS your biogas will be upgraded to pure methane. The biomethane can be supplied to the national gas grid, or be compressed to Natural Gas to be used as vehicle fuel.

DMT’s Carborex MS in Poundbury, UK, was the first commercial biogas upgrading system in the UK, and the first in Europe in 2012. DMT is now the largest producer of biogas upgrading facilities in the world with membrane technology. In 2016, we sold the biggest biogas upgrading plant in the USA. Biogas upgrading contributes to the creation of circular economies and energy independence.

Out of wastestreams clean gas can be provided to houses as well as fuel for transport and mobilty. Biomethane is fossil-free, it is the energy of the future.

Product Description

Biogas Upgrading to green gas or vehicule fuel; Carborex MS

The biogas upgrading process can be performed with the Carborex MS, which separates methane from carbon dioxide by the use of membrane technology. This process has the advantages that it is a dry process (no chemicals involved), it has low energy consumption and is easy to operate. The whole system is built on a skid or in a container which results in a low footprint and easy transportable system. It is therefore a clear cleantech solution with low operational costs (OPEX).

Membranes

The membranes inside the Carborex MS are built up of hundreds of hollow fibers which looks like spaghetti. The hollow fibers are non-porous and made of polymers. The separation of methane and Carbon dioxide occurs because of the difference in diffusivity. The molecular structure of carbon dioxide allows this molecule to pass through the polymer material faster than does the molecule of methane. Biogas enters the membrane inside the hollow fibers. The separation results in a carbon dioxide rich stream at the permeate side of the membrane and a methane rich stream at the retentate side of the membrane.

Pre-treatment and compression

As mentioned before, biogas consists mainly of methane and carbon dioxide. However there are still some other components that have to be removed before entering the membranes. For example, biogas contains in many cases also H2S, Mercaptans and Terpenes which have to be removed. But also the gas contains water which is preferably removed before entering the membranes. For this reason the Carborex MS contains a pre-treatment section where these components are removed. The next step is to compress the gas up to 16 bar by a compressor. The pressure optimized the separation of the methane and carbon dioxide by increasing the permeability of the membrane.

Multistage vs Single stage

One membrane contains hundreds of hollow fibers, the Carborex MS contains many membranes. Depending on the inlet flow the amount of membranes inside the Carborex MS can vary. Even though a membrane separates CO2 from CH4, the selectivity of one membrane is not 100%. This means that at the end of one membrane, the methane flow still contains a certain amount of Carbon Dioxide. To achieve high purity of methane at the end of the process therefore another set of membranes are placed after the first set of membranes. We call one set of membranes a stage. The multi-stage process can in this way achieve methane concentrations of > 98%. On the permeate side, because of intelligent recycle loops, the methane concentration in the carbon dioxide stream can be reduced to <0,5%.

Easy operation

The Carborex MS is an excellent example of what DMT calls Plug&play technology. The whole system can be start up with one simple touch on the start button. The system is robust and stable. Therefore the system has low maintenance. Because it is a dry process, no after-treatment of waste streams is required.

End Products

The biomethane from the Carborex MS can be used for several purposes. As the bio-methane is a replacement for natural gas, it can be injected inside the natural gas grid. In case no gas grid is available the gas could be used as transport fuel. In this case the gas is compressed to 250 bar as bio-CNG or liquefied (-162 degrees Celsius) as Bio-LNG.

Bio-LNG product description

Liquefied green gas

Liquefied Natural Gas, from the liquefaction of high quality biomethane, can take pride in being the only bio-fuel better than its fossil counterpart. Research shows that Bio-LNG is the most cost effective fuel available today for CO2 emissions reduction and therefore an ideal investment for reaching climate goals. By combining clean combustion, easy transportation, flexibility and higher security both in terms of reserves capacity and stability of price, Bio-LNG is gaining access worldwide as the fuel of the future. And DMT can make it.

Carborex®LNG in four steps

After screening already established as well as promising new technologies, common problems associated to the liquefaction of biogas (like the presence of contaminants and the freeze out of components such as CO2 and H2O) were overcome by developing a process comprising of four steps. First the biogas is pre-treated for the removal of toxic and harmful contaminants and H2O. Next the biogas is upgraded and polished by membranes in the unique plug-and-play Carborex®MS . Finally the gas is liquefied in a Carborex®LNG and ready to be distributed to fuel stations.

See Carborex MS’ product description on DMT’s website.