BAUER GRU® XL DUPLEX

The BAUER GRU® XL DUPLEX biogas compressor is designed for larger flow applications where extreme turn-down and redundancy are required. The BAUER GRU® Biogas Recovery Compressor range has been specifically designed for methane recovery and conditioning in biogas applications.

The function of the biogas recovery compressor is to elevate the pressure of the incoming biogas from 1-7 PSIG (typical) to 90-230 psig, which is the operating pressure requirement for most PSA/membrane type gas conditioning systems. BAUER offers a complete BAUER GRU® system size range from 10 HP to 750 HP (7.5-560 kW).

Product Description

BAUER GRU® XL DUPLEX: Biogas Membrane Feed Compressor for Larger Applications

The BAUER GRU® XL DUPLEX biogas compressor is designed for larger flow applications where extreme turn-down and site redundancy are required. The BAUER GRU® Biogas compressor range has been specifically designed for the biogas upgrading process. The function of the biogas compressor system is to elevate the pressure of the incoming biogas from 1-7 psig (typical) to 90-240 psig, which is the typical operating pressure requirement for most PSA/membrane type gas upgrading systems.

The most comprehensive size and performance range in the industry

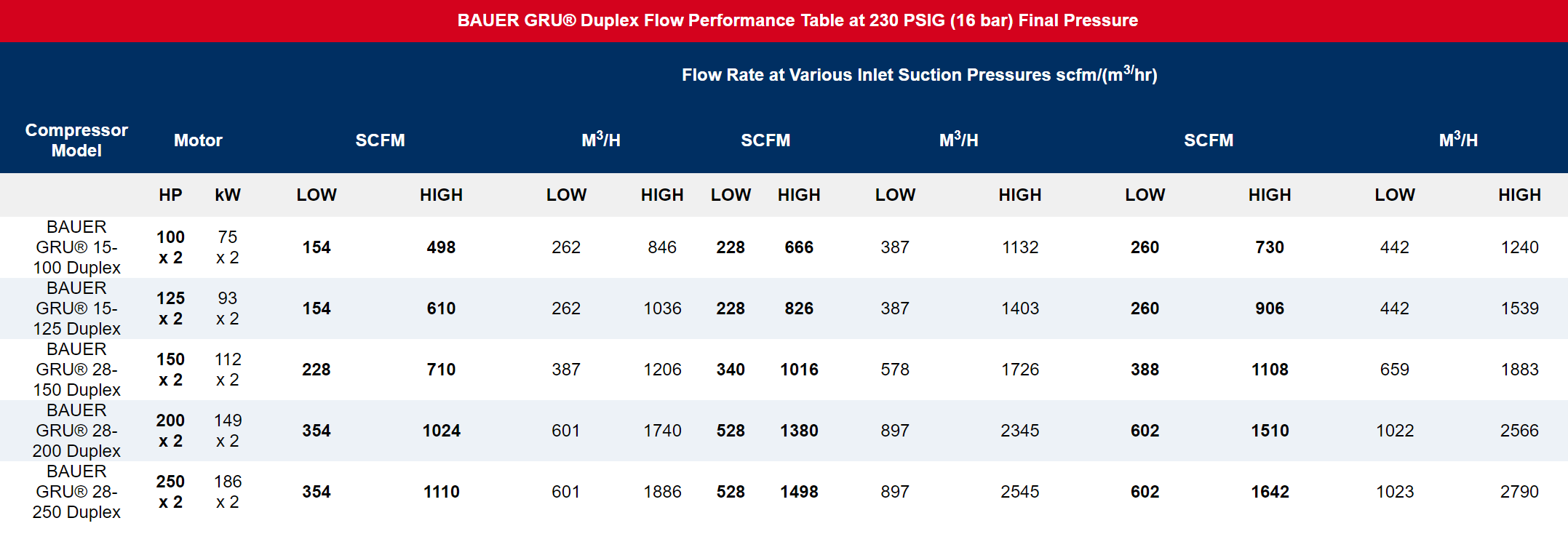

BAUER offers 5 different sizes and models of the GRU® Duplex Biogas Compressor System, ranging from 250 to 500 HP (150-370 kW). This range allows BAUER to size the compressor system specific to the performance requirements of each individual biogas upgrading project.

- Horsepower range: 250-500 HP (150-370 kW)

- Biogas Flow Rate: 500-1600 scfm (850-2790 nm³/h)

- Typical dimensions with enclosure and vent stacks: 216.5” L x 96.5” W x 154.3” H (5499 mm X 2451 mm X 3919 mm)

- Dimensions without enclosure and vent stacks: 216.5” L x 96.5” W x 96.1” H (5499 mm X 2451 mm X 2441 mm)

Standard scope of supply

- Heavy-duty rotary screw compressor manufactured by BAUER’s Rotorcomp® division at the heart of the system

- Variable speed control of compressor to modulate the flow of biogas based on the incoming supply of gas (VF drive located remote from skid as defined by Class 1, Div 2 code requirements per NEC NFPA70

- Heavy-duty TEFC electric motor

- Stainless steel construction of piping and major P&ID components

- PLC control of all major system components

- BAUER CONNECT® remote telemetry IoT with full remote HMI control function, historical reporting, SCADA and AI-driven self-diagnosis

- Fully integrated system built on a heavy-duty steel skid designed for plug and play installation

Available options include

- Gas inlet particulate filter

- Gas aftercooler (air-cooled)

- Heavy-duty weatherproof enclosure

- Sound attenuation

- Ultrasonic testing of piping welds (100% material NDE traceability for process components)

- Hydro testing of piping and relevant components (100% material NDE traceability for process components)

- Modbus TCP/IP or Profinet connection to customer’s control network

- Special certifications and documentation

- CE electrical code, CRN pressure vessel code

- Heat recovery

- Cold weather package

All BAUER GRU® compressor systems are designed and manufactured in the USA in accordance with US and Canadian standards and are backed by BAUER’s legendary Customer Support and Lifecyle Performance guarantee.