Biogas Purification Systems

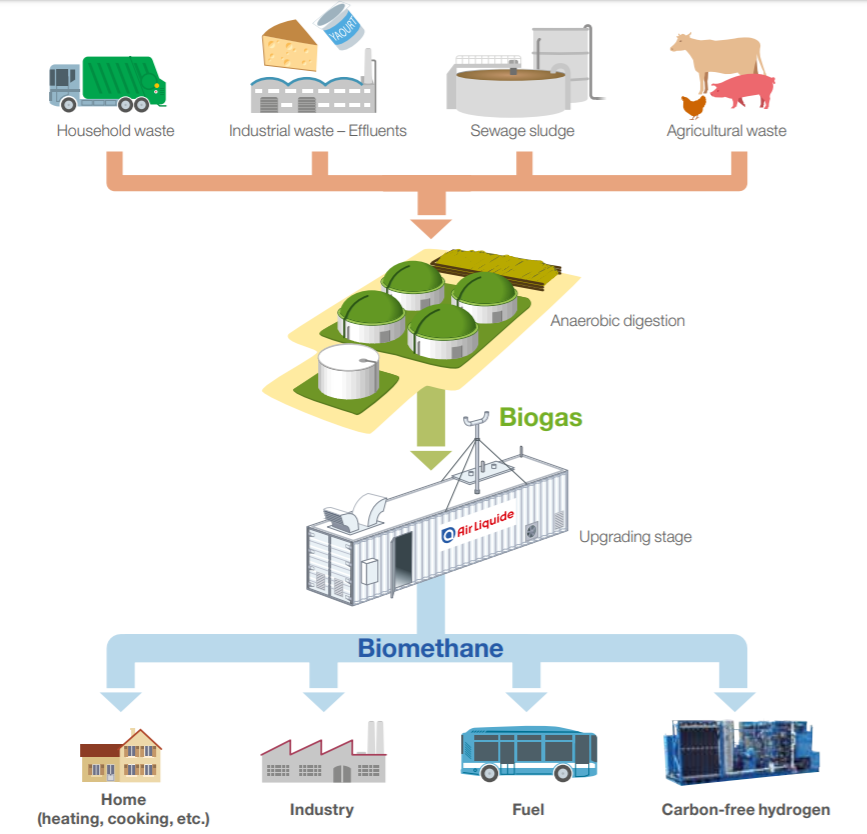

In order to turn the biogas into a substitute for natural gas, we need to remove the carbon dioxide (CO2) and the pollutants. Air Liquide has developed a technical solution that now allows biogas producers to efficiently turn it into biomethane using purification processes. The technology used to separate the two main components of biogas – methane and carbon dioxide – is based on the use of polymer membranes produced by Air Liquide Advanced Separations (ALaS). This efficient system generates biomethane with a methane (CH4) content of between 96.5% and 99%, depending on its purpose. With its technical solution for biogas purification, Air Liquide takes charge of every stage of processing, from when it leaves the digester until it is injected into the gas network.

Product Description

The Air Liquide Biogas Purification Systems: Gas separation Technology

Air Liquide’s purification modules separate methane and carbon dioxide via an innovative process that uses polymeric hollow fiber membranes made by Air Liquide (Medal*). This efficient system generates high quality biomethane (CH4 content from 96.5% to 99%). Combined with a process reaction event unit, all of the biogas is upgraded.

Key Benefits

- Guaranteed quality for injection into the network

- Methane recovery rate > 98% (up to 99.5% with additional solution package)

- High energy and environmental performances (no utility other than electricity)

- Simple and reliable system (run time > 98%)

- Economical and highly efficient

The liquefaction of biomethane

Liquefaction opens up other avenues for biomethane recovery. The liquefaction of biomethane appears to be an appropriate solution in cases where logistical constraints arise due to the absence of a transportation network. In liquid form, biomethane is easy to transport to its point of use. Air Liquide offers industrial liquefaction units that are adapted to your needs.

Key Benefits

- Energy consumption is optimal

- Process is reliable and efficient

- Technology is well-understood and well-managed

Turnkey Biogas Upgrading Solutions

Air Liquide offers you turnkey solutions for biogas upgrading suited to your needs: purification, injection, cryogenic distillation, liquefaction. Our experts support you every step of the way, from the design phase to the delivery of the operational unit.

Thanks to the development of several technological bricks, including the CO2 separation membranes our solutions enable you to upgrade all biogases for injection into the natural gas grid, the production of vehicle fuel, liquid biomethane, and the production of renewable hydrogen. The modular systems designed and developed by Air Liquide are upgradeable biogas processing units with processing capacities that range from a hundred to several thousand m3 an hour (100 to 10,000 Nm3/h). The recognized expertise of Air Liquide in the area of industrial gases, combined with the experience we have acquired in biogas purification, are major strengths that ensure the success of your projects.