Omnivore: Anaerobic Digester Upgrades

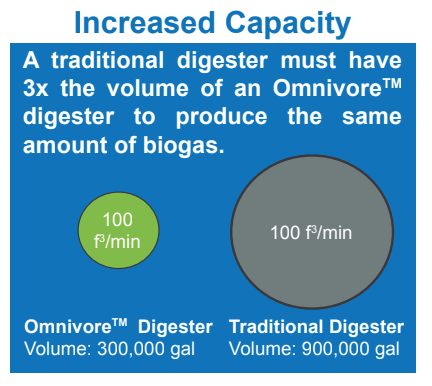

The OmnivoreTM retrofit package can triple the capacity and biogas production of a traditional anaerobic digester, as well as process streams with high solids content.

Files

Product Description

Anaerobic digestion upgrades: Increase Digester Capacity with a retrofit

Overview

Municipal wastewater treatment is an energy-intensive process. The solid portion of municipal wastewater (sludge) is high in energy value which can be made available for energy production via anaerobic digestion.

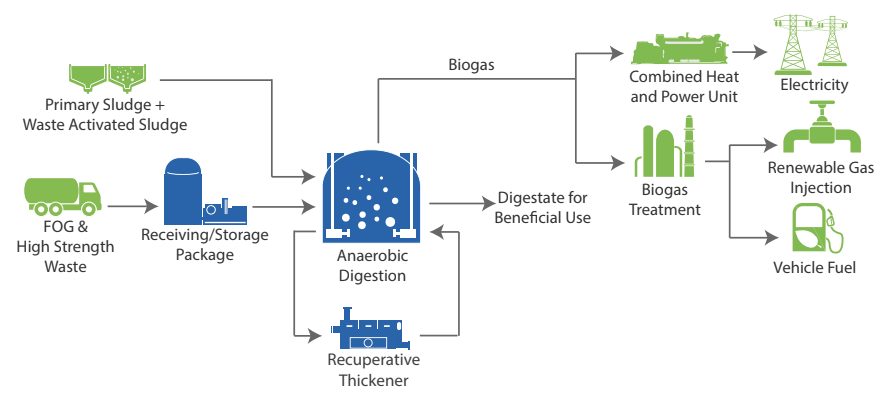

The Omnivore retrofit package offers wastewater treatment facilities the ability to convert existing digesters into high-solids Omnivore digesters, significantly increasing biogas production while ensuring continued wastewater treatment efficacy. The Omnivore retrofit package increases solids loading and biogas production through the recuperative thickening, high solids mixing, and external feedstock digestion.

Applications of the anaerobic digestion upgrades

• Transform a wastewater treatment facility into a renewable energy production facility.

• Increase the capacity of existing digesters by up to three times.

• Enable reception and co-digestion of high strength waste streams such as fats, oils, and grease, or the organic fraction of municipal solid waste. This increases biogas production and creates revenue from tipping fees.

• Reduce foaming potential with high-torque mechanical mixing.

Benefits of the anaerobic digestion upgrades

• Increase capacity without the cost of an additional digester.

• Create energy neutral wastewater plants.

• Triple gas production to produce more electricity and heat.

• Use co-digestion to optimize existing digester space.

Components of a Full Omnivore Retrofit

Omnivore retrofits are engineered for unique site conditions and facility goals. The components can be used individually to meet a specific need, or can be combined to make a full Omnivore retrofit package.

Substrate Reception

Liquid feedstock is processed in a rock trap and grinder before it is stored and fed to the Omnivore digester. Reception enables co-digestion which produces more biogas, and brings the plant closer to energy neutrality.

High Solids Mixing and Service Boxes

Anaergia’s unique hydraulic and electric mixers handle liquids with high viscosity and high solids content. The patented service box allows for mixer access and safe maintenance while the digester is still operating.

Gas Storage

To provide consistent gas feed for electricity production, a double membrane digester cover is installed. It withstands external loads while providing additional gas storage volume to an existing digester.

Recuperative Thickening

Anaergia’s proprietary recuperative thickener is the key to increasing digester solids by separating digestate into filtrate (to headworks) and solids (returned to the digester).

For more information, please visit Anaergia’s website.