TerraVest Launches Manufacturing Capabilities to Renewable Gas Industry

Recognition that the global movement to reach net zero emissions by 2050 would require immediate and sustained effort from all levels of society – individuals, businesses and governments – made it a simple decision for TerraVest Industries to enter the renewable energy sector. With core strengths in gas processing and equipment fabrication, it was a natural and seamless progression for TerraVest to offer integrated clean energy solutions through a new Renewables Division to do its part to fight climate change.

While installations of renewable energy facilities reached an all-time high in the past year, faster deployment is needed to reach the 2050 net zero target. This fact prompted TerraVest to make another easy decision, that of offering its manufacturing capabilities to other renewable energy project developers to spur industry growth.

“Canada is harnessing only about 14%[1] of its biogas and RNG potential through its 279 projects while the 2,200 plus sites in the US represents only about 15%2 of potential development,” commented Jason Greene, President of the Energy Processing Equipment Division at TerraVest Industries. “This contrasts with Europe where there are over 10,000[2] biogas operations allowing some communities to rely mostly on clean energy. By working with other renewable gas developers, we can support the installation of more low carbon energy systems at an accelerated pace to reach emissions targets.”

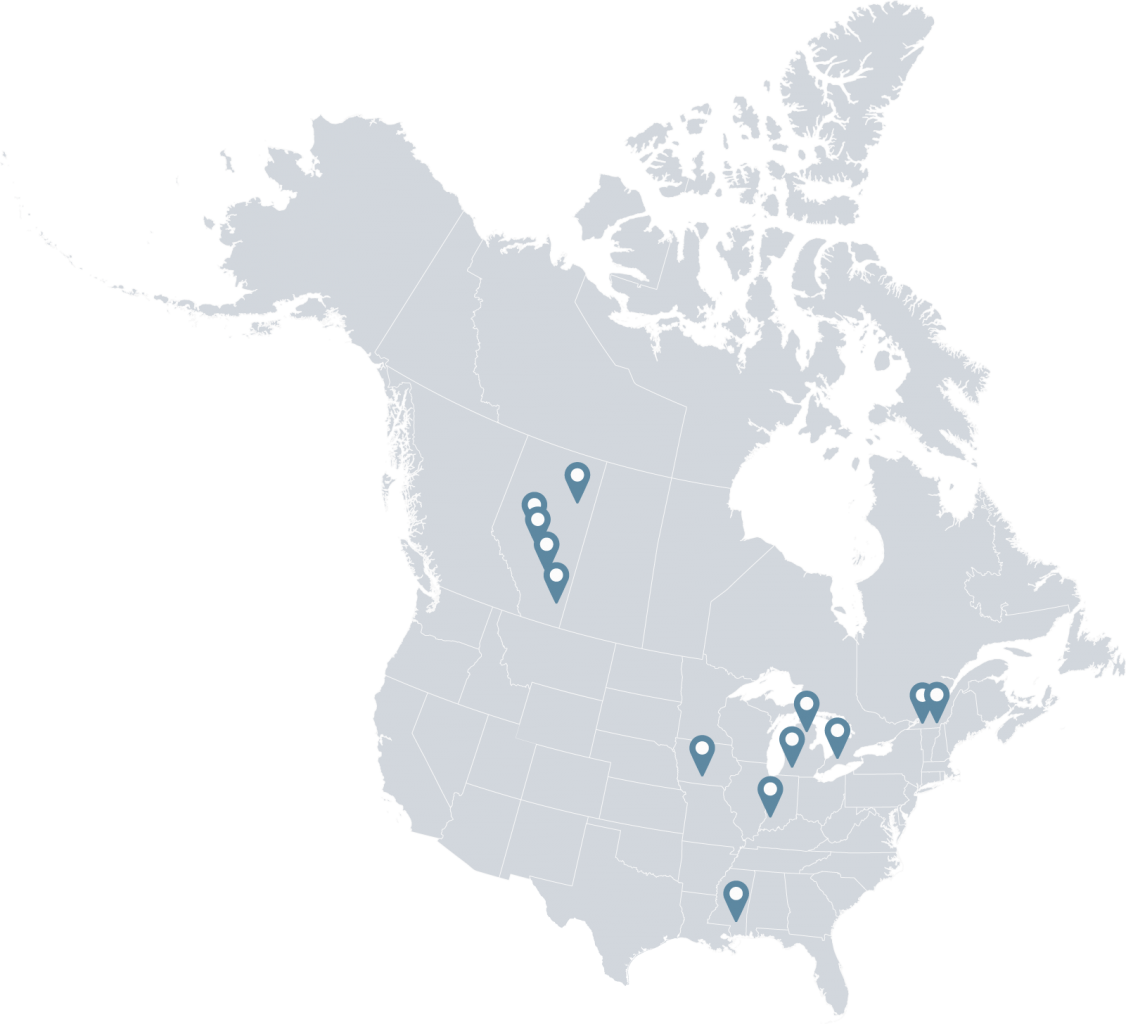

The manufacturing capabilities of TerraVest consists of more than a dozen vertically integrated facilities across North America. Many of these facilities have been in operation for more than five decades with some the recipient of gas industry awards for supplier excellence.

This longevity and acknowledgement equates to extensive experience in the design and production of high-quality gas processing equipment adhering to industry standards, codes and specifications. And the wide geographical reach provides numerous access points for the renewable gas industry to procure equipment and servicing to meet the scheduling requirements of their projects.

“It was very beneficial to have access to an established manufacturing infrastructure when we entered the market,” said Jason Bridges, General Manager for TerraVest Renewables. “The reassurance it provided to have a trusted supplier of high-quality equipment who could fabricate what we need, when we need while remaining competitively priced, was definitely a factor to us securing our first RNG project within a year of being in the industry.”

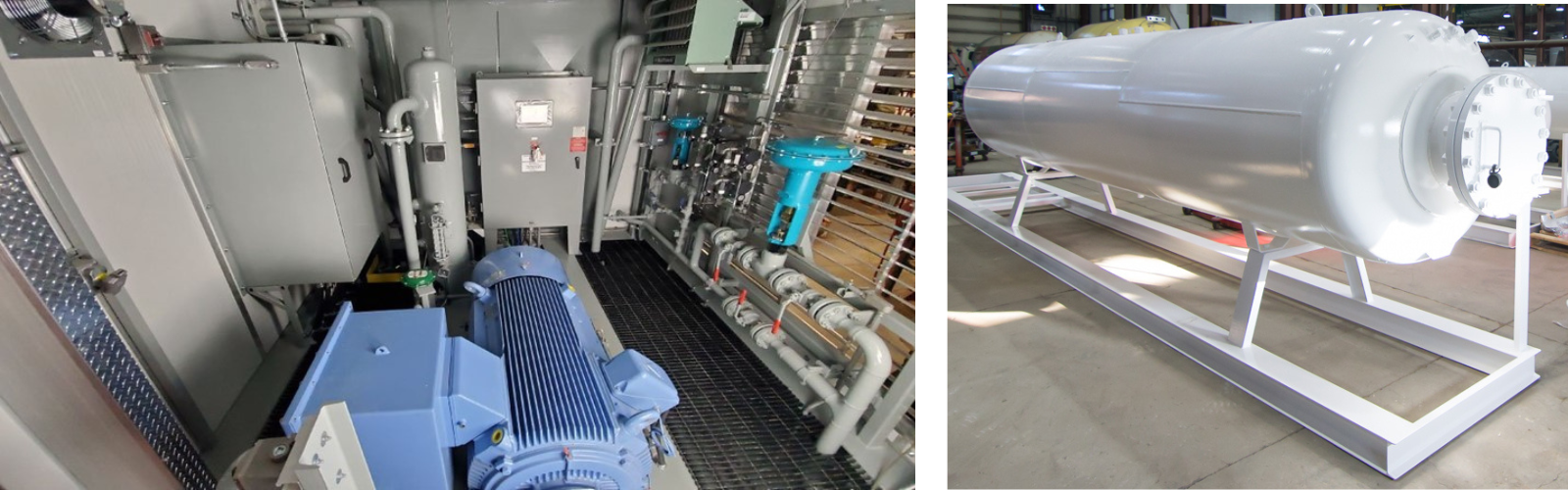

With vertically integrated manufacturing, there is full control of the entire production process from start to finish. All structural, pressure vessel and pipe welding fabrication are completed in-house along with painting, electrical and instrumentation by trained and experienced tradespeople. The result is reliable equipment for high mechanical availability and a production schedule that meets project deadlines.

Adds Jason Greene, “We pride ourselves on manufacturing process equipment that meets not only the required design specifications outlined by our clients but that also passes our rigorous factory acceptance testing. Our quality control programs are industry leading.”

More information about TerraVest Industries is available on their website www.terravestindustries.com and any enquiries may be directed to Jason Greene at jgreene@terravestindustries.com.

[2]US & European data https://americanbiogascouncil.org/biogas-market-snapshot/