What is the Future of Small-Scale Anaerobic Digestion Plants?

UPDATED: 2023/01/10

Although anaerobic digestion of small amount of organic and food waste was considered unprofitable a few years ago, it is growing today with a new model of biogas production: small-scale digestion plants (or micro-scale digestion). By the end of 2016, 130 micro-scale digestion facilities were in operation in Europe. Smaller, less expensive, easily self-sufficient, these production units attract farmers, but also investors in eco-neighborhoods, wishing to develop new sources of clean energy.

There are over 20,000 full-scale AD systems in the world and over 1,000 new projects per year. However, the valorisation process for organic waste can still be optimized. One way to do so is to use small-scale digestion. Today’s trends: modular approaches (e.g. in containers), mobile units and “plug and play”.

What is Small-Scale Digestion?

Small-scale digestion involves the production of biogas, but on a small scale within farms or small communities. The small-scale digestion production units are below 80 kW. Most agricultural units have a power capacity between 100 and 300 kW, while some industrial units exceed 1,000 kW.

A small-scale digestion project is carried out starting from 100 dairy cows or 200 cows or between 200 to 5000 tons of organic waste per year. ”The interest for small-scale digestion is not to have to invest in large facilities,” explains François Xavier Dumur, Nov & Atech Project Manager. ” Small-scale digestion allows the autonomy of the system by supplying the digester with the farm products.”

Micro-scale and home anaerobic digesters are very common in Asia and Africa, specifically in remote rural areas and small communities. There are reportedly millions of household digesters in China, with a previously set target of 80 million digesters by 2020. In most cases, given the low feedstock, the volume of biogas produced isn’t enough to cover the cost of construction and digester management.

In a recent interview with Waste Management World, our president Maxime Lemonde pointed out “In Asia or Africa, a small-scale digester will be a home digester for mainly human waste and some food waste. This means that when we talk profitability, it’s mostly for European and North American projects”.

Small-Scale On-Farm Anaerobic Digester

The development of micro-scale digestion on-farm plants emerged after 2010. Agriculture is truly well fit to be juxtaposed with anaerobic digestion for many reasons. It helps farmers:

- Produce their own power and heat, and therefore save money;

- Reduce greenhouse gases related to livestock manure and energy consumption;

- Reduce the strong odors associated with the use of untreated manure as fertilizer;

- Minimize the need to transport the organic inputs for treatment to the proximity of on-site facilities;

- Benefit from the advantages of digestate: more liquid material and therefore easier to spread, fewer weeds and mineralized nitrogen, etc.

In France, this energy alternative is becoming very successful, particularly in Brittany, where a dozen projects are planned. For farmers, small-scale digestion is a good way to diversify their activity at a reasonable cost.

Comparing a Large-Scale Plant to Small-Scale Plant

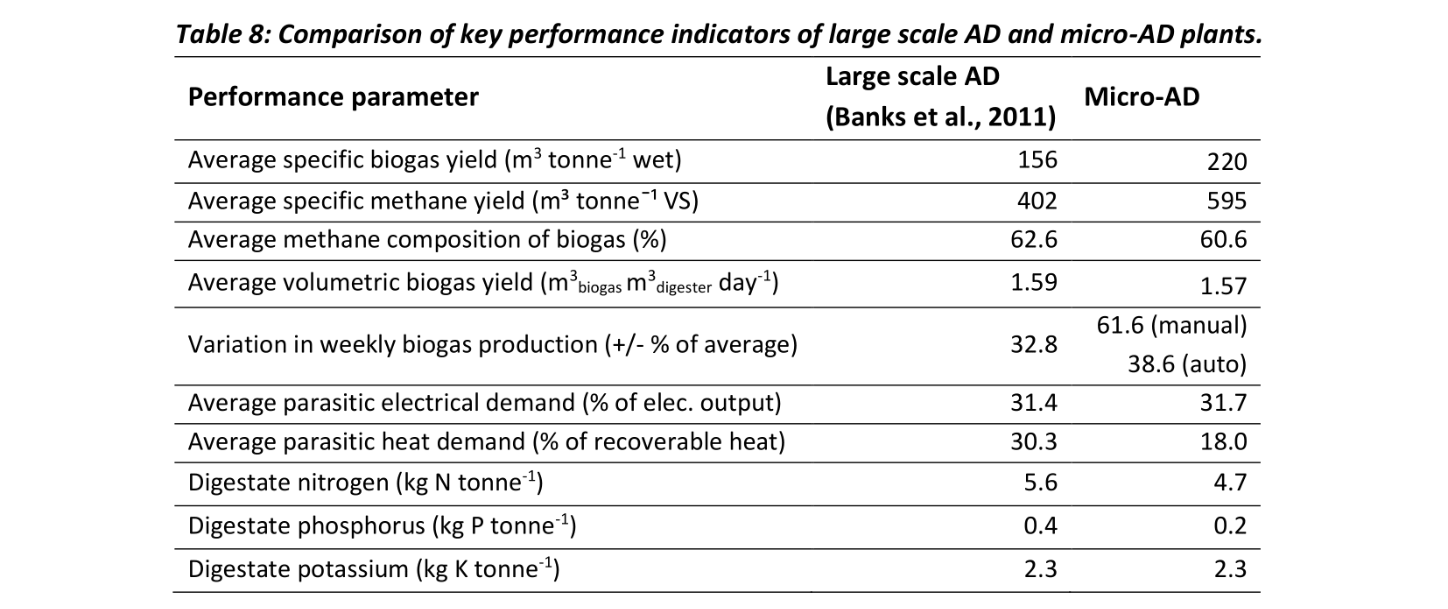

Here is a comparison of key performance indicators from a 900 m3 commercial anaerobic digestion system fed on food and green waste and a 2m3 small-scale anaerobic digester fed on apple pomace, catering waste, coffee waste, tea leaves, oats, water and soaked paper bin liners.

Source: Walker, M., Theaker, H., Yaman, R. et al. (5 more authors) (2017) Assessment of micro-scale anaerobic digestion for management of urban organic waste: A case study in London, UK. Waste Management. ISSN 0956-053X https://doi.org/10.1016/j.wasman.2017.01.036

In this case study, the performance of the micro-scale AD system is similar or slightly better than the large-scale system. The authors explain that the choice of an appropriate scale should rather be based on external factors, such as collections, waste quantities, distribution of production, digestate usage and economical analysis.

Are Small-Scale Units Financially Viable?

In France, electricity produced from anaerobic digestion facilities can be sold to EDF, the country’s national electric utility company. Therefore, small-scale anaerobic digestion complements the income from dairy farms. A project can range from 150,000€ to 450,000€, depending on the size of the chosen unit.

Business models are built to be profitable within 10 years for small installations and less than 5 years for bigger systems. A project’s profitability varies from 10 to 22%, depending on your system’s power. It is however important to remember that each installation is different and that a feasibility study must be carried out to determine the precise size of the unit and thus estimate its profitability.

Estimated profitability of micro-methanization units according to power in France

Source: NORIAP. Microméthanisation: quelle rentabilité? June 23, 2020. https://www.noriap.com/blog/la-micro-m%C3%A9thanisation-pour-compl%C3%A9ter-les-revenus-de-son-%C3%A9levage-laitier

Small-Scale Digestion Technologies

HoSt Microferm – HoSt Bioenergy Systems

HoSt Microferm is designed for farmers who want to process manure from their own installation. Depending on the size, the farm can produce between 60 and 150 kWe green energy. Apart from the production of electricity and heat, the formed biogas can also be upgraded to natural gas quality and be supplied to the natural gas grid.

The solution consists of a digester and a container in which the control is located, and a Combined Heat and Power connection (CHP) or a biogas upgrading system. The biogas upgrading or the gas engine supplies the heat for the digester.

BEKON MINI – BEKON

The BEKON MINI dry fermentation system offers BEKON serial technology for entirely new markets and in a fully new dimension.

The advantages of BEKON MINI:

- Dry fermentation in a minimal space

- Low capital and operational expenditures

- Especially suitable for low input quantities

- Effective decentral electricity and heat generation

Valentin – PlanET Biogas Solutions

The VALENTIN biogas plant offers the newest digester size in the PlanET fleet. Its small, modular design is specifically targeted toward farms that have not been able to implement larger digester projects. Like all other PlanET digesters, the VALENTIN benefits from our 20 years of experience designing and building best-in-class digesters.

MyGug

MyGug is a new Micro Scale Anaerobic Digester. It is a food Waste treatment system that fully integrates into a household/small food business setting. It will operate in all weathers and climates from -20 deg C to +40 deg C . It will provide a clean fossil fuel free solution to disposing of food waste and turns that waste into free energy for your use.

BioQUBEs – QUBE Renewables

BioQUBEs are robust, modular small scale anaerobic digesters (biogas digesters) providing a compact solution to process smaller volumes of feedstocks and wastes on site. The systems can be configured for each site to allow multiple digesters running from a single feed system along with biogas storage, energy generation and digestate pasteurisation.

HomeBiogas

HomeBiogas provides the ultimate experience: aesthetically pleasing, quick assembly, low-maintenance, durability, and convenient use. Join the family, and start producing homemade energy today! In the newest generation of household biogas systems, it has never been easier to turn your waste into energy!

A Handbook to Help You Develop Your Small-Scale Digestion Project

Published by Bioenergy Farm, the handbook « Implementation Guide for Small-Scale Biogas Plants » accompanies you in your microscale digestion units project. Different topics are discussed:

- What steps should I follow to achieve my project?

- What technology should be chosen and what size adapted to my operation?

- What legislation applies to my project and what assistance can I get

- What financial assistance can I get for my project?

- How can I ensure that the project is profitable?

- Etc.

The Right Supplier at the Right Time

BiogasWorld will be pleased to help you to achieve your small-scale anaerobic digestion project. We have a large network in the industry. We can help you find the right suppliers at the right time to facilitate the development of your project.

Do you hesitate to contact us at info@biogasworld.com or to schedule a meeting with us.

Sources

- Bioenergy Farm : Market Overview, micro scale digesters

- La Tribune: Micro-méthaniseurs : la solution pour mieux valoriser les déchets en ville ? (French only)

- l’EnerGEEK: Micro-méthanisation : une opportunité énergétique sérieuse ? (French only)

- Pleinchamp: La petite méthanisation trouve un écho chez les agriculteurs (French only)

- Paysan breton: 2017, cap vers la méthanisation à la ferme (French only)

- Energie & Environnement: La micro-méthanisation, marché de niche ou véritable potentiel à court-terme? (French only)

- Le-Gaz: La micro-méthanisation prendra-t-elle son envol en france ?

(French only) - l’EnerGEEK: Méthanisation : ségolène royal allonge les contrats de rachat de l’électricité de 15 à 20 ans (French only)

- Waste Management World: What about small scale anaerobic digesters?

- Walker, M., Theaker, H., Yaman, R. et al. (5 more authors): Assessment of micro-scale anaerobic digestion for management of urban organic waste: A case study in London, UK.

- NORIAP: Microméthanisation: quelle rentabilité?