Syngas and Hydrogen Compressors and Packages

Applied Compression Systems provides durable and customizable syngas compressors for optimal gasification process performance.

Files

Product Description

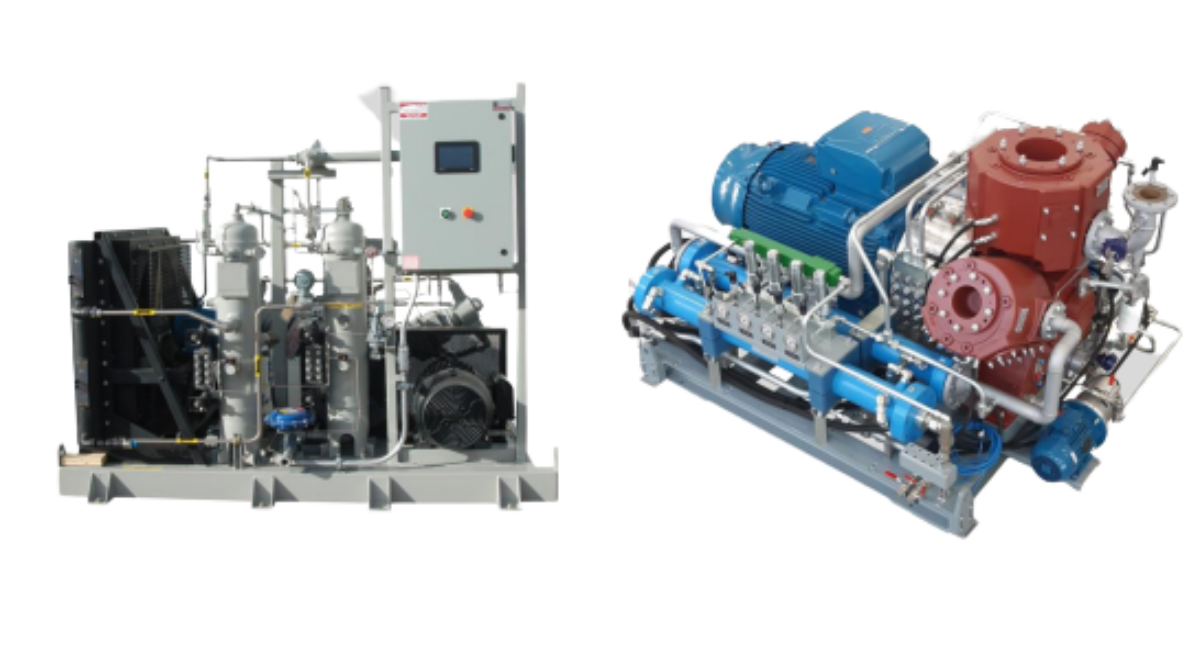

Syngas and Hydrogen Compressors and Packages

Syngas is a mixture of Hydrogen, CO2, CO, and CH4 predominantly with about 50% of the energy density of natural gases. It is used as a fuel source or cleaned into its base components for use.

Syngas and Hydrogen compression requires a gastight, leak-free compression system. ACS has solutions that are purpose built for these applications utilizing rotary vane, roots, reciprocating, rotary screw, and diaphragm compressor technologies. We design, engineer, and fabricate compression solutions that are a perfect fit for the recovery of synthesis gas from pyrolysis and gasification phases of biomass decomposition. As well as for Hydrogen refueling systems which require oil-free compression and pressures up to 750 BARG.

Our Packages are designed to handle the potential for corrosion, hydrogen embrittlement and meet the electrical requirements that are related to syngas and Hydrogen compression. With the selection of oil-free compression ACS can also provide contaminant free compression solutions. All our packages can be provided as open skid mounted systems up to complete walk-in style buildings designed for ambient temperatures down to -50C.

Our different models and packages

- Low Pressure Syngas Blower Packages: We have developed a complete range of SynGas blower packages for pressures up to approximately 15 PSIG (1 Bar G). We offer side-channel, centrifugal and rotary lobe blower options for syngas applications. We can provide expert assistance in selecting the right blower, the right options and the right accessories for your application.

- Intermediate Pressure Syngas Compressor Packages: These compressors are ideally suited for pressures up to 35 PSIG for air-cooled units and 50 PSIG for water-cooled compressors. Mapro rotary vane compressors, are designed to provide years of continuous service in corrosive syngas applications. Wear is limited to vanes, bearings and shaft seals resulting in reduced maintenance costs and with fewer moving parts, Mapro rotary vane compressors are easily field repairable. Each compressor supplied by us includes a comprehensive set of operating manuals and data sheets. Every compressor package is completely assembled and tested under load to make sure it leaves our plant in perfect operating condition.

- Medium Pressure Syngas Compressor Packages: Our medium pressure packages are designed specifically for the material and electrical requirements that are related to tough SynGas applications. This modular design makes it possible for us to find the optimum solution for each specific case, both from a technical and economical point of view. These packages are available with a locally mounted and pre-wired control panel or with the end devices wired to a junction box for control by a main plant PLC. Also available are variable speed drive systems that evenly match gas compression volumes to gas production rates. In periods of low demand, the VFD reduces the gas flow rate by reducing the drive speed. This reduction in speed saves power and trims operating costs. Our goal is to provide superior, high reliability compressor packages that translate into lower operating cost and increased profits for your company.

- High Pressure Syngas Compressor Packages: We also offers a complete range of preengineered high-pressure reciprocating compressor packages for applications requiring pressures up to 5000 PSIG. Our reciprocating packages range in size from 5 to 750 HP (3.7 to 560 kW) and offer a clean, simple design that allows easy access for normal maintenance. These compressor packages are available as a simple skid-mounted unit or housed in a weatherproof enclosure or walk-in style building for cold climate locations.

Features

- We offer North America’s widest range of syngas compressor packages and blowers.

- Shop costs are much lower than those of field construction.

- Many of the packages that we offer have been pre-designed for quick turnarounds.

- Our flexible modular design allows us to quickly and economically plan and fabricate a compressor package to meet individual customer specifications and industry specific applications.

- Each compressor package manufactured by us comes with a set of in-depth parts and operating manuals so you can clearly understand the operation and maintenance requirements of the equipment.

- On completion, you are provided with detailed quality control documentation including material test reports (MTRs), hydro-test reports, x-ray certificates, welding qualifications, weld mapping, ASME U1A forms etc., ensuring safe equipment operation for years to come.

- Whether you need a package to be shipped within Canada, across North America or overseas we can assist with final shipping arrangements to your site.

For more information, visit our website or download our technical brochure.