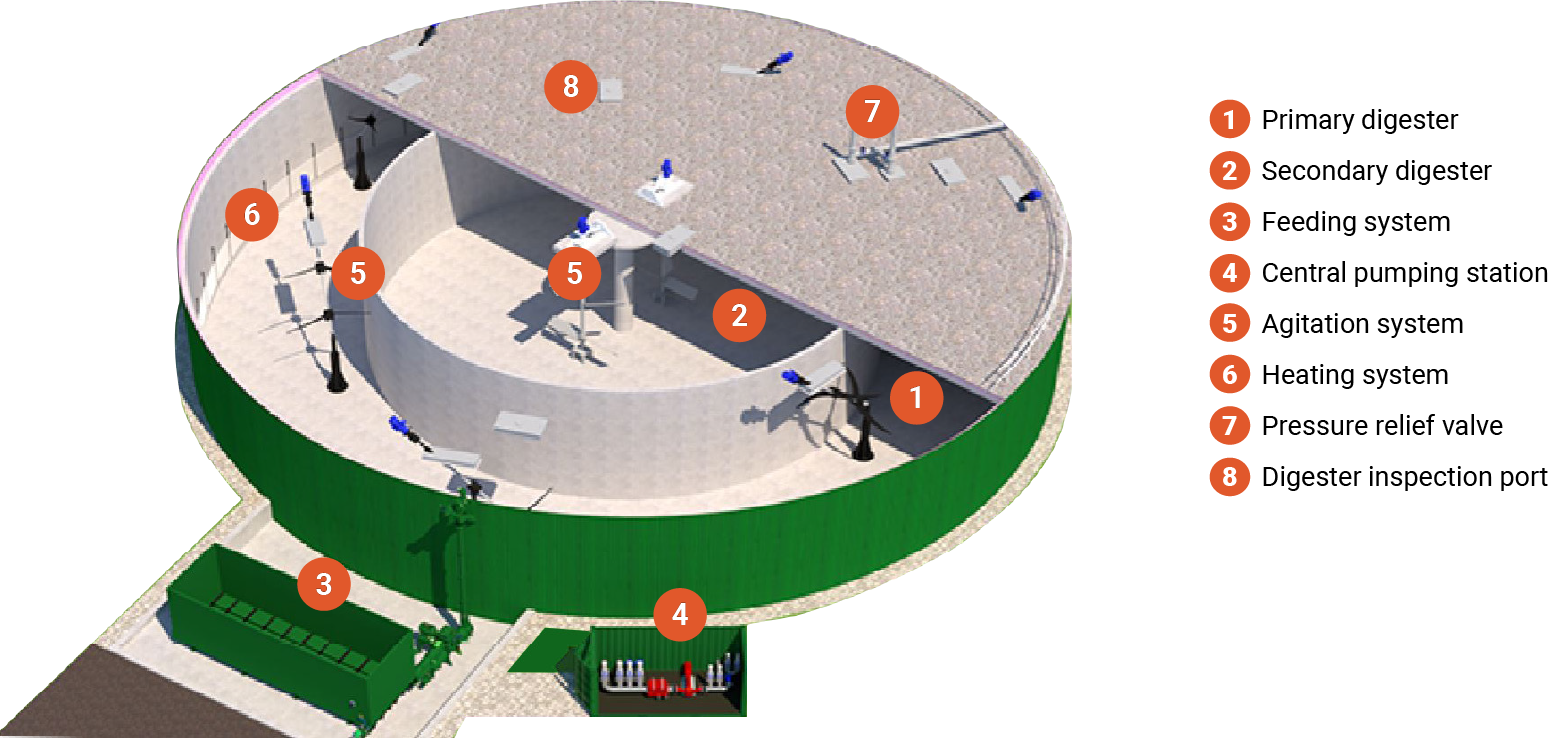

BIOGEST PowerRing

The BIOGEST PowerRing is a highly efficient, 2-stage biogas plant which is suitable for operation with almost all substrates. Power output ranges from 250 kW to 2,000 kW and a biomethane production of 80m³/h to 500m³/h. The design is based on an external main digester and an internal post-digester. The main digester is a ring canal, thereby allowing a controlled plug flow.

Product Description

The BIOGEST PowerRing digester is equipped with a reinforced concrete roof, and complete insulation guarantees the highest levels of thermal efficiency. Due to the compact design of the plant, the tank can be simply scaled to the size required according to the desired output and the type and quantity of substrate.

A special characteristic of the BIOGEST PowerRing system is its outstanding agitation technology which has already proven its worth during long-term operation in several reference plants. Scientific studies using simulations have determined the ideal positioning of the agitators in order to achieve the best possible level of mixing and minimum energy consumption. Their ease of accessibility and external motors makes servicing the agitators a very simple procedure.

Solid substrates are fed into the main digester using a solid substrate feed system, while liquid substrates are pumped. Using gravity and with no additional energy input, the fermented material (digestate) leaves the main digester via spillways, first into the post-digester and then to the final storage or intermediate buffer. The BIOGEST PowerRing draws on an extremely low proportion of the power it generates thanks to the agitator technique, feed in system and overall design.

The plant is completely automated and controlled via a user-friendly operating system. All the measurements and parameters which are of greatest importance to the biogas process are logged, allowing the plant processes to be recorded and permanently monitored on an ongoing basis.

Click here to see more information on the website of BIOGEST.