Pump Selection for Biogas Plants with the Future in Mind

“Money is not an object”, said no project manager or investor ever! In fact, and unfortunately, the viability of many biogas facilities relies exactly on how inexpensive it will be to get to start up – and then operate.

Nobody involved in building a new plant will recommend that you compromise for your budgets sake. Nor should they.

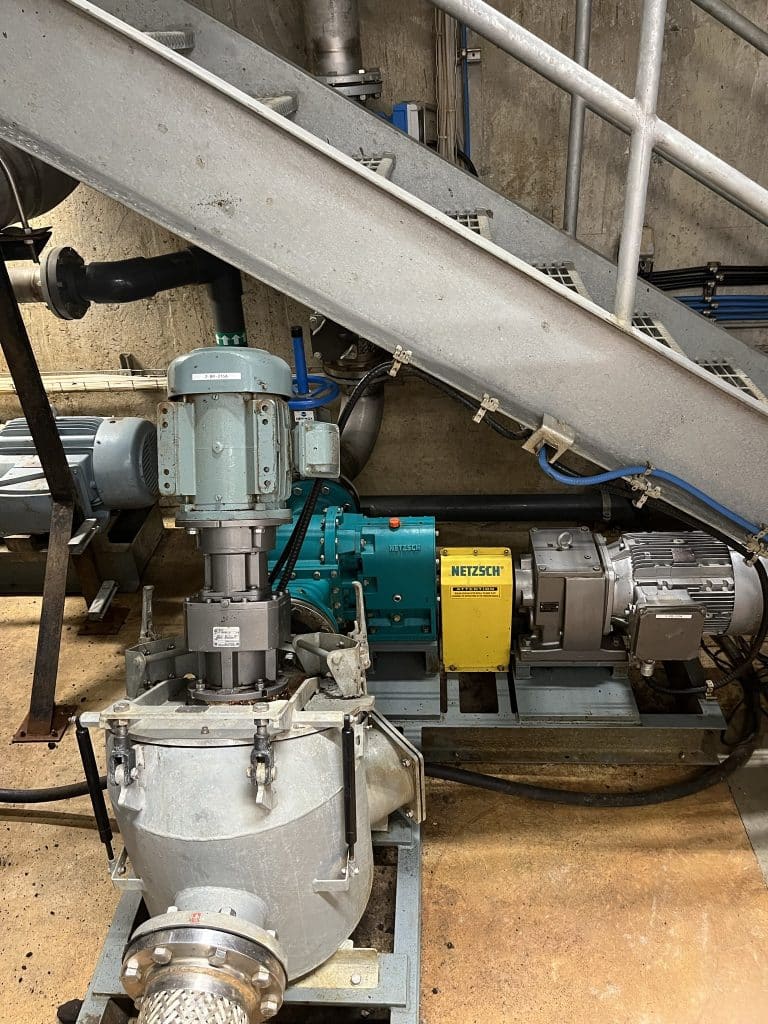

When added up, the sum of the costs of the fluid handling and conditioning equipment in a medium to large sized biogas facility constitute a capital investment.

If you’re fortunate enough to work directly with a pump manufacturer right from the design phase they will explain why the following are so important for future considerations; Pump selection, Versatility, Quality, and Support.

The Right Pump (or Grinder) – Selection is the key

How many of you recall sending back pump application data sheets with key information missing? Information like particle size, NPSHa, % of solids, whether or not there are any chemicals present, or temperature, etc. It happens far too often.

Companies that provide complex fluid pumping solutions shouldn’t make assumptions. As a stakeholder, without the proper data, you will never get an accurate budget from a manufacturer. At least not from a good one. A good engineer will always assume the worst case – and when talking equipment, that always means more expensive.

Moral of the story when talking about data? The more, the better.

Fluid handling equipment manufacturers that offer multiple solutions will look to offer the best fit for your application, as opposed to trying to fit your application into their potentially limited product range – therefore if given the choice, try to get the manufacturer involved at the design or spec phase.

Versatility – More birds with less stones

Many biogas facilities are designed and built with the expectation that capacities will increase, and that incoming products will change. With more data, a manufacturer can recommend potential standardizations of pump sizes, as well as material selection – to have interchangeability for all pumps of a certain type – saving space, money, and time.

Quality & Support

Future proofing is as much about ensuring the manufacturer of the equipment you are buying will be around in 5 years to support you, as it is worrying about how much your applications and processes may change. Do yourself a favor and work with reputable vendors – or it may cost you.

For more information and biogas projects, read BiogasWorld’s Canadian Biogas Magazine.