Latest Drycake Twister Depackaging and Separation System in Canada Commissioned in Montreal

The Montreal waste authority has introduced a significant advancement in sustainable waste management with the commissioning of the Drycake Twister Depackaging and Separation System by the Société d’Économie Mixte de l’Est de la Couronne Sud (SÉMECS), in partnership with Drycake and EG Biogas.

This initiative reflects the authority’s broader commitment to reduce organic waste sent to landfills and to reduce carbon emissions.

It not only separates recyclable materials but also produces an organic pulp conducive to biogas production, highlighting a shift from waste disposal to extracting value from these materials.

More specifically it enables:

- the organic content to be treated by anaerobic digestion where the energy is extracted from the organic matter such as waste food, to make valuable renewable energy in the form of biogas.

- A potential in the future for the rejected material such as plastics to be recycled, or for their heat energy to be used in refuse-derived fuel (RDF).

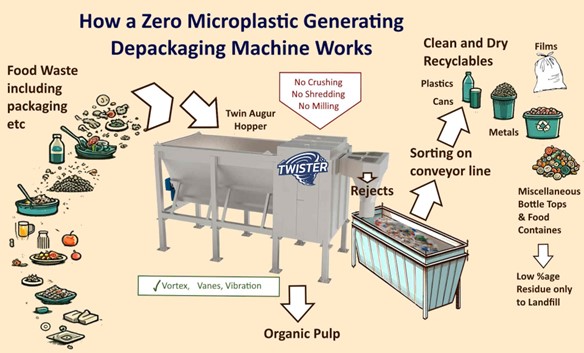

The Drycake Twister system is designed to process municipal source-separated organic waste, including green garden waste and household food waste, with a capacity of 8 to 12 tons per hour. With their 25 years of experience in separation technology, Drycake developed and patented the Twister, as a third-generation vertical cyclonic separation system that unlike competitor products:

- does not create microplastics and

- provides an industry leading quality of organic output, while also ensuring a clean dry reject output with large pieces uniquely suited for subsequent recycling.

The system’s integration into Montreal’s waste management operations is notable. It begins with waste reception, moving to the Twister unit for depackaging and separation. The Twister Seditank unit further treats the organic material, removing inert materials such as grit and glass, which enhances the quality of the material for energy extraction.

The environmental and operational advantages of the Drycake Twister system are clear. It helps divert waste from landfills, reducing methane emissions and supporting the circular economy through waste reduction, recycling, and sustainable energy production. Moreover, its low energy requirement (3.5 kW) and compact size (18 square meters) underscore its efficiency.

In summary, the Drycake Twister system in Montreal represents a key development in the city’s waste management strategy, focusing on sustainability and efficient energy use. This project underscores the potential for innovative technologies to contribute to environmental goals and waste management efficiency across Canada.

For more information and biogas projects, read BiogasWorld’s Canadian Biogas Magazine.