10 tips to reduce the costs of your biogas / RNG plant and increase its profitability

How can you reduce the costs of your biogas or RNG project and increase its profitability? Evaluate the costs of a biogas plant, learn about what impacts it, potential revenues and other benefits it generates. Thus, you will be better equipped to act on certain key aspects of your project and optimize it. Are you ready to find out how to better evaluate and plan your biogas project?

The evaluation of feasibility and profitability and project planning are the starting points for any biogas and RNG project. Here’s how to take advantage of this step to improve your project.

What does the cost of a biogas plant generally include?

The evaluation of the costs of a biogas plant includes several important aspects. Be careful, however: be rigorous. The following expenses tend to be underestimated or not taken into account during cost planning.

Construction and Infrastructure Costs (CAPEX)

The costs of a biogas plant construction and getting the necessary infrastructure include equipment, engineering, materials and labor as follows:

- Land(s)

- Designing, building and commissioning of the biogas plant

- Redundancy and phasing of the biogas plant

- Type of technology chosen

- Automation of the process

- Process to achieve the desired digestate and biogas quality

- Laboratory premises and offices

Operating and maintenance costs of a biogas plant (OPEX)

These expenses are connected to the management of a biogas plant, such as its operation, maintenance and personnel. More specifically, this category of costs includes, among others:

- Labor force for the operation and maintenance of the biogas plant

- Spare parts, maintenance and repair of equipment

- Purchase, collection and transportation of feedstock

- Consumables (polymers, filter medias, etc.)

- Energy (electricity, natural gas, etc.)

- Transport, sale or spreading of digestate

- Laboratories analysis

- Insurance, taxes and interest

So, how much does it cost to build a biogas plant?

Estimating the cost of operating and building a biogas plant or RNG project can be complex. It depends on various factors, such as its size, location, type of inputs or technology chosen.

Here are some examples of general prices:

- CAPEX costs: between $ 400 and $ 1,500 per wet ton of material. Thus, a simple farm installation would cost about $ 400/ ton. A municipal unit with waste sorting and biogas purification systems could cost up to $ 1,500/ton.

- OPEX costs: between 1 and 10% of CAPEX

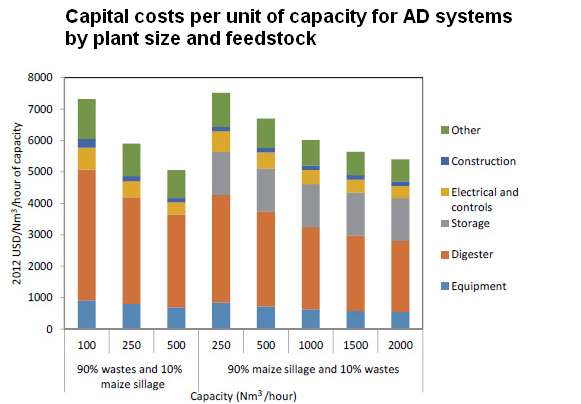

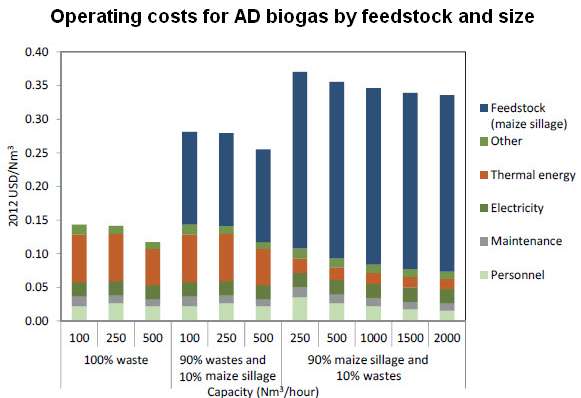

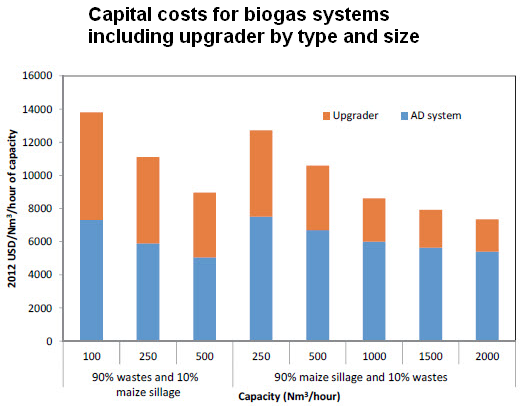

To give you an idea of how the different factors impact the costs, take a look at the following graphs:

Source : CleanLeap

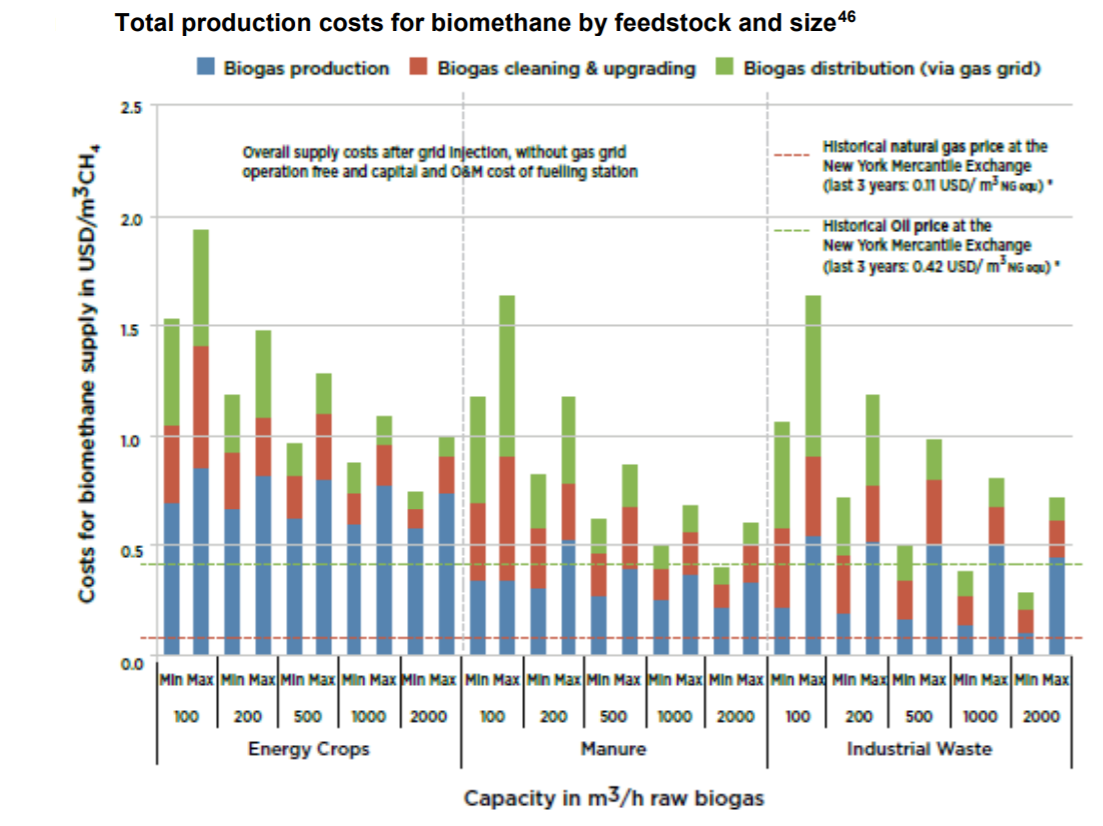

In addition, a researcher from the Oxford Institute for Energy Studies offers a different perspective. The study published in 2017 determines the production costs of biogas and RNG based on the discounted energy cost (LCOE). It is calculated using the initial investment, the operating and maintenance costs and the service life of the equipment.

The LCOE of biogas produced from a digester is between 6 and 14 USc / kWh, depending on the cost of the selected feedstock. It is comparable to wind energy, which is between 6.8 and 12.6 USc / kWh.

RNG, meanwhile, has an LCOE between 4.7 USc / kWh and 15 USc / kWh, or between 0.5 US $ / m3 and 1.5 US $ / m3. These production costs include the upgrading of biogas into renewable natural gas and its distribution in natural gas networks.

Here is a graph summarizing the costs of RNG production and biogas purification plants, and the factors influencing them:

Source : University of Oxford

Do not hesitate to contact a professional company to have your project evaluated. Indeed, hundreds – even thousands – of other aspects influence the price and can increase or decrease the bill.

How to reduce the costs of a biogas or RNG plant while increasing its profitability?

By optimizing certain aspects of your biogas or RNG plant, you can reduce costs and make it more profitable. Here are 10 tips to do it.

1. Maximize biogas production by volume of input

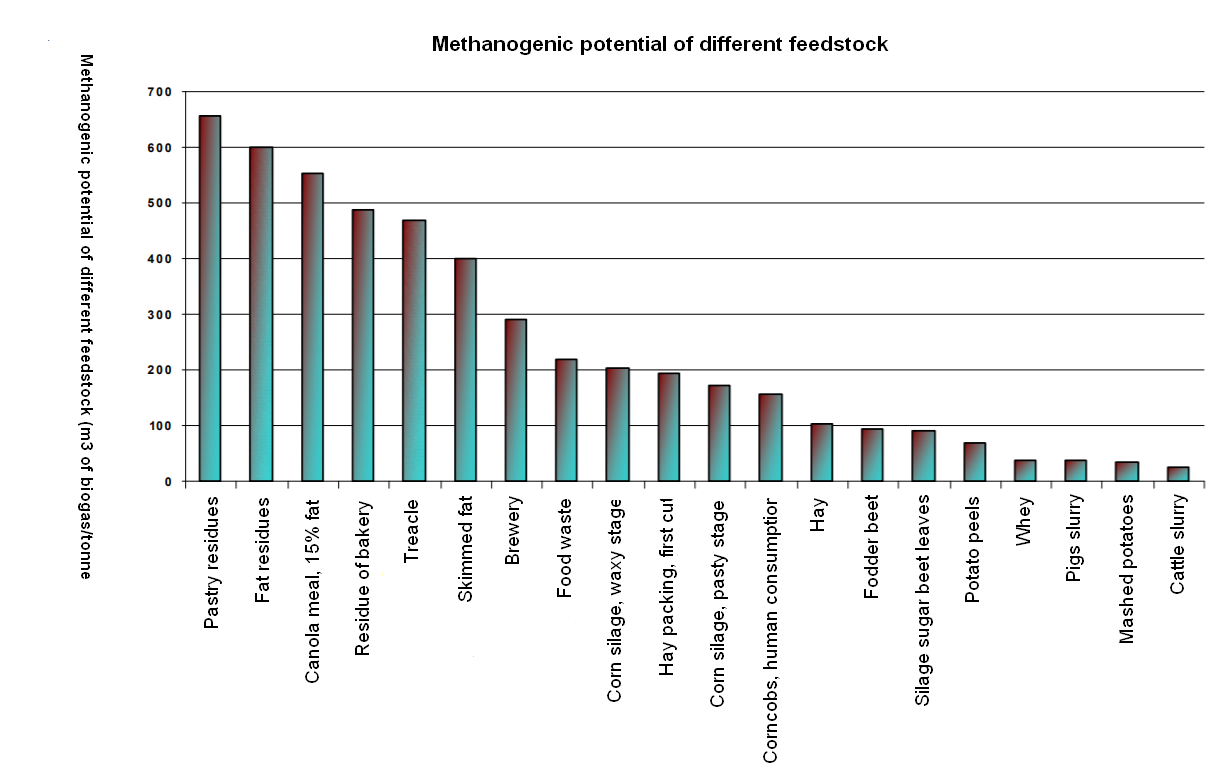

To do this, you can promote certain mixes of feedstock with high methanogenic power, adopt good practices to manage feedstock or optimize the process.

For example, according to Agri Réseau, pork manure is one of the least methanogenic feedstock. However, you can maximize its potential when you mix it with fats, for example.

Source : Agri Réseau

To maximize biogas production by volume of feedstock, you can:

- Ensure proper storage of feedstock, especially manure and slurry because they lose long-term methanogenic potency

- Pay attention to the choice of feedstock

- Improve your waste pre-treatment processes, such as grinding and hydrolysis technologies

- Optimize biological processes in the digester

2. Choose feedstock in order to limit costs

Choosing the feedstock that will be processed in your biogas or RNG plant is a strategic decision. Indeed, the cost will vary depending on the type of feedstock you chose and the level of waste pre-treatment or conditioning before anaerobic digestion process.

For example, you can get free manure from a farm or sewage from a WWTP. Management and storage infrastructures therefore exist even if there is no anaerobic digestion plant. So, you save money on some of the infrastructures you need for your plant because you can use existing ones.

The cost of energy crops can be up to US $ 40 / ton. Moreover, a study published by ENEA Consulting recognizes the significant costs involved in purchasing energy crops for several biogas plants in agricultural areas. The advice is to implement various cost reduction strategies, such as maximizing yield per hectare.

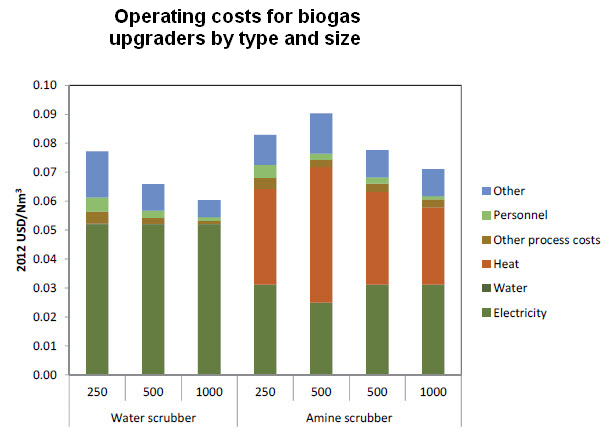

3. Choose a biogas production or upgrading technology that allows quality product at a limited cost

The selected biogas production or upgrading technology will undoubtedly influence project costs. For example, some types of feedstock require further processing to become a quality product. In this case, the process will cost more.

You must also consider the use of biogas and its associated products, as well as the quality needed to choose the technology. Indeed, if you get a poor digestate as a product of anaerobic digestion, you will have an additional cost of up to 30% of your OPEX. In fact, you will have to send your digestate to compost or even landfill it. Similarly, the biogas upgrading and its conversion to fuel entail additional costs.

Evaluate, from the first stages of the project, what use of biogas, RNG and other associated products would be the most profitable for you.

Here is a graph summarizing the costs of a biogas upgrading or purification plant:

Source : CleanLeap

4. Secure local feedstock and ensure a local use of biogas / RNG to reduce transportation costs

First, make sure you have access to enough organic waste stably to supply your biogas plant. This way you can optimize your mix of feedstock and make your project viable.

One way to reduce the costs of a biogas plant is to focus on local sources of feedstock and uses of biogas. In fact, converting local waste into biogas rather than using energy crops reduces the cost of transporting feedstock. Manure and residues from wastewater and those from agri-food industry, among others, are often available locally and perceived to be greener.

In addition, you can produce heat and electricity for buildings or equipment near the production site to increase the profitability of your project. If the demand is insufficient, you can also upgrade your biogas in RNG and inject it into the local grid. This solution reduces energy distribution costs.

5. Use the produced biogas to the maximum

Investing in reliable and high-quality equipment will help you make the most of the biogas you produce. This will help you get more out of your biogas plant while reducing your costs.

For example, you can choose to use some of the produced biogas for your own needs to maintain the temperature of the digester. In this case, you must invest in equipment that improves the insulation of digesters and gasometers and the efficiency of boilers to limit energy loss.

Despite the purchase of good equipment, you may not be able to inject all the produced RNG because of constraints beyond your control. These factors consist of, for example, limitations of the gas network or the reduction of the quality. In this case, you could negotiate a more flexible arrangement with your local energy grid or find other ways to use the energy.

6- Optimize the maintenance of biogas or RNG plants

Another way to reduce the costs of your biogas plant is to ensure its rigorous, planned and optimal maintenance. Why?

Maintenance helps you anticipate potential equipment breakdowns and other problems that may occur in the process. It also extends the life of your biogas plant. This way, you can avoid unpleasant surprises and stabilize the income generated by your plant.

In addition, we advise you to sign turnkey maintenance contracts that include availability guarantees. This is a good way to ensure the rigor of the performed maintenance.

To learn more, take a look at our article on maintaining a biogas plant.

7- Choose the construction of larger biogas plants

Several studies note show that the larger the biogas plant is, the more expensive it is, but the more profitable it is. This has a significant scale effect on CAPEX and human resources costs.

For example, according to a study from the International Renewable Energy Agency (IRENA) published in 2013 on Clean Leap :

- A small-scale plant (production of 250 Nm3 / hour of biogas) would cost between US$ 4,400 and US$ 5,950 / Nm3 / hour

- A large-scale plant (production of more than 2000 Nm3 / hour) would cost around US $ 1,950 Nm3 / hour

See the graphs in the section about the costs of a biogas plant to see the impacts of plant size.

But pay attention: the costs of managing feedstock and digestate, including the transportation and storage, increase with the size of the biogas plant. The same is true for energy distribution costs. The key to success is finding a balance between the size of the plant and the anticipated costs.

8- Increase the value of your anaerobic digestion plant by extending its life span

Currently, the life of a biogas plant is estimated at 15 years. In reality, however, you can extent your biogas plant life over a much longer period of time, over 25 years, for example.

If you produce biogas over a longer period of time, you can add value to your initial investment and reduce operating costs.

9- Carefully design the biogas plant and its process

To reduce the costs of your biogas plant construction, you must pay close attention to designing the plant and its process. For this purpose, the experts of BiogasWorld offer you the following advice:

- Choose the site of your plant carefully. If the land is unsuitable for this type of construction, you will have to carry out other works such as soil reinforcement or decontamination

- Optimize the quality of the digestate to avoid having to get through one more composting step. However, you are not obliged to obtain AAA level quality for your digestate

- Optimize the redundancy if needed and avoid oversizing during plant planning

- Measure the benefits of a LEED building or a building that is too big

- Look carefully for the benefits and costs of different business models (municipal, mixed economy, etc.)

10- Make sure you have the necessary financial and human resources

Calculate accurately the expenses associated with staffing, training, taxes and the amount of grants obtained. You will avoid surprises because they are a large part of the costs of a biogas plant. For example, a larger plant will require more employees to function.

The following general tips might help you:

- Transfer, to a certain extent, the level of risk of the project to the suppliers

- Get performance guarantees and compensation

- Evaluate the amount of mandatory taxes and subsidies you can get in the country where the plant will be located

- Ensure the level of competence and training of project stakeholders

Finally, what are the keys to the success of your project? Here are some solutions.

Source : BiogasWorld

A biogas project, is it profitable today?

Along with the expenses associated with the project, there is as well the question if the production of biogas brings any profits. The answer? Of course, it does, if you take into account the potential revenue and the other benefits of biogas.

Income from a biogas plant

How can you get a good return on your biogas or biomethane plant to make it more profitable? Here are some examples of potential revenue for your biogas plant:

- The sale of energy, such as heat, electricity or biomethane. Some countries offer advantageous feed-in tariffs and subsidies

- Fees received for waste treatment

- The sale of the digestate produced during the AD process

- The sale of environmental credits, such as GHG emissions

- Savings from using biogas to run farm equipment producing it or as an alternative to composting

Check with relevant government offices or professional associations for detailed information. Note, however, that the available options and the associated revenue may vary by country and facility type.

The benefits of biogas are not just about money!

The profitability of a project is not only calculated in terms of revenues and costs. Biogas production has other environmental, economic and practical benefits that can have positive impact on community stakeholders, including project developers.

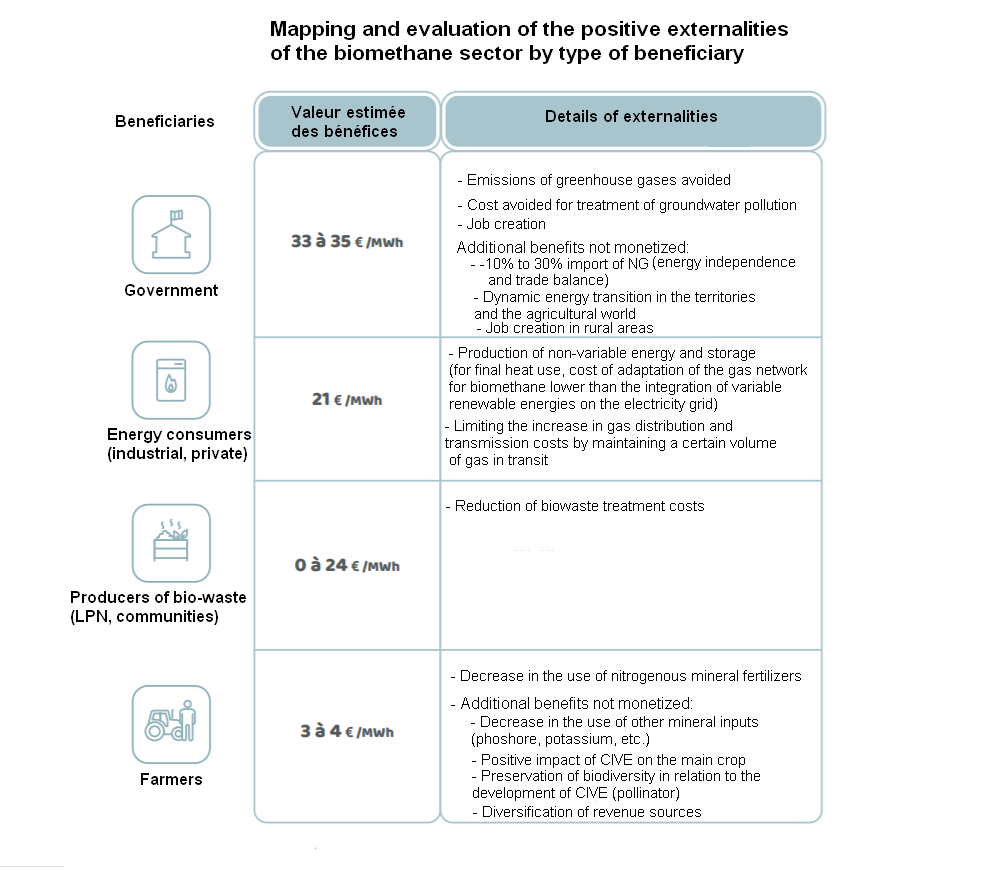

When evaluating the profitability of your project, make sure to add these additional benefits to the costs and revenues of your plant. Also known as positive externalities, they include:

- Reduction of greenhouse gas and methane emissions

- The production of green energy that can be stored and is continuously available

- Creation of green jobs

- Growth of the economy in rural areas

- Reduction of the costs to treat organic waste and its landfilling

For example, ENEA Consulting, in a study published in 2018, attempted to quantify or qualify the impact of RNG in France.

Source: ENEA Consulting

The production of biogas / RNG is undeniably a profitable investment for all. If you can take action to make your project profitable, governments also have work to do to better regulate the sector and stimulate its growth.

For the moment, several governments around the world already offer subsidies, loans or other financial support for biogas / RNG projects. Take a look at our articles on legislation and funding for biogas and GNR and project financing in North America.

Successful projects in the biogas and biomethane industry

Released in September 2021, our Showcase Report 2021 highlights over 65 successful stories within the industry from BiogasWorld members. From large-scale projects converting organic waste to energy, to small-scale anaerobic digestion systems, renewable natural gas can be used in various fields of applications.

Our free report has been designed to introduce you to these technologies and services, presented in a short description highlighting their results and benefits. You will get a glimpse into which technologies and services are currently offered in the biogas and biomethane market all over the world.

Experts to guide you in a biogas / RNG project

There are several things you need to consider to reduce the costs of your biogas / RNG plant and make it more profitable. The challenges are numerous and can vary according to the country, the installations, the sites, etc. How to navigate?

Operations and project design experts can become real compasses for developers who are looking to navigate the plant development process. Check our online catalog for suppliers. Plan your project with our project evaluation tools.

SOURCES

- Méthanisation agricole : quelle rentabilité selon les projets?, Cairn Info

- Biogas: A significant contribution to decarbonising gas markets?, University of Oxford

- Costs of a biogas plant, Energypedia

- New Fuels for transport: the cost of renewable solutions, CleanLeap

- Renforcer la compétitivité de la filière biométhane française, ENEA

- Guide de méthanisation à la ferme : Outils d’aide à la décision, Agri Réseau