How to prevent or reduce the odors of a biogas plant?

The odors of a biogas plant are at the forefront of the concerns expressed by citizens when such a project is implemented in the territory. Project developers must, therefore, take into account this key issue to promote the success of the biogas plant and keep harmonious cohabitation with the local communities. How to prevent or reduce the odors of a biogas plant using an odor management strategy? What solutions can developers implement during the design and operation of the plant?

Please note: This article is written for general information using publicly available sources mentioned below. If you are planning a biogas project, please make sure to connect with a professional company to discuss applicable standards in your country.

What causes the odors in a biogas plant?

In itself, the process used to produce biogas, in other words, the fermentation of materials in a completely hermetic environment, is odorless. Odors associated with biogas plants may be caused by several inefficiencies listed below:

- use of non-hermetic equipment or logistic mechanisms, especially when transporting, storing, unloading or loading materials

- choice of non-appropriate solutions in the context of the project, ineffective or lack thereof solutions

- breakage of essential equipment to reduce odors

- weather conditions and the time of day, for example, the direction of the wind during a specific stage of the process

- flaws in the planning or coordination of certain plant activities

In short, the developer must understand the issues that may arise and find the specific causes of the problem. This will help find the appropriate solution.

Managing the odors of a biogas plant: where to start?

To reduce the odors of a biogas plant, or to prevent them, the project developer starts by establishing a strategy. It is a step to do at the design stage of the project or once an odor problem arise during the operation of the plant.

In addition, the project developer must ensure compliance with all regulations associated with the odors of a biogas plant.

To develop this odor management strategy, the project developer should:

- evaluate the odors that emanate or could emanate from the biogas plant

- provide solutions to prevent unwanted odors during the operation of the plant

- provide solutions to reduce odors if they can not be avoided

- choose appropriate solutions to monitor the odors during plant operation

- establish the communication plan with the local community, such as citizens and elected officials, to build a trusting relationship with them

Evaluate and monitor the odors of a biogas plant

Evaluating odors that come from or could come from a biogas plant is the basis of an effective odor management strategy. This analysis is essential both at the project implementation stage and during the plant’s operation.

It makes it possible to plan appropriate solutions to prevent and reduce odors or to make adjustments to technologies already in place. The odor evaluation includes:

- origin of the odors

- Potential sources of odors in biogas production at each stage of the process

- perceived intensity of odors

- composition of the odors emitted by the treated materials and their characterization

- frequency of exposure of citizens to odors

- intermittency or persistence of odors emitted

When designing the project

During project design, rigorous planning is required to assess and prevent the odors of a biogas plant.

The impact study consists of the initial evaluation of odors in the place where the plant will be located. It acts as a point of reference and includes the analysis of the plant’s impact on the environment and the mitigation measures to be taken.

The project developer must also pay attention to the chosen location of the plant. For example, the distance between the plant and residential area or frequently used/visited areas and the source of the treated materials will be of importance.

During the operation of the plant

The regular evaluation of the odors coming from the biogas plant, the follow-up and the monitoring of these must be part of the operation of the project. Through an audit, the developer will evaluate the factors mentioned above in case of odor problems will determine the source of these problems and find the solution.

In addition, the project developer must carry out odor monitoring throughout the operation of the biogas plant in order to:

- anticipate smell problems

- be able to warn the population of unpleasant odors to come

- monitor the effectiveness of implanted solutions to reduce odors

- ensure compliance with the regulations in force

Choosing the right solutions to reduce the odors of a biogas plant

The project developer can choose from a wide range of solutions to prevent and reduce odors coming from a biogas or anaerobic digestion plant.

What is the best combination of solutions? To get the answer to this question, the developer must look at the specific characteristics of his project and the odor analyses done previously.

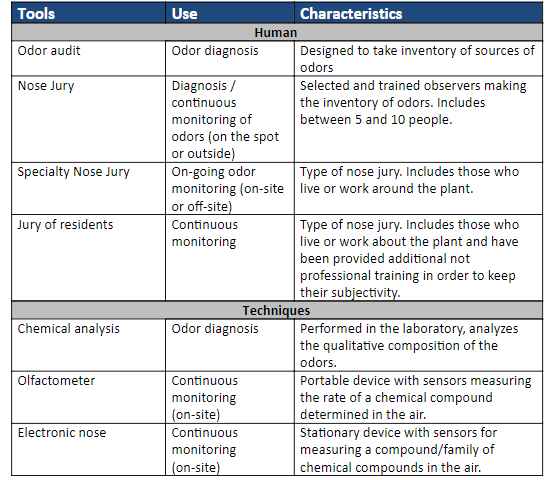

1.Odor assessment and monitoring tools

Here is a summary of the odor assessment and monitoring tools:

2.Odor treatment technologies

In addition, the project developer can implement other solutions to deal with odors impossible to avoid. Here is a table summarizing the different technologies available:

3. Solutions associated with logistics and biogas plant process

Solutions to prevent and reduce the odors of a biogas plant also apply to its logistics and processes. These must be carefully planned and optimized, especially when they involve the transport, storage, unloading or loading of organic materials.

Here are some general recommendations :

When transporting materials

- the vehicles must be completely airtight and the material must not be in contact with the outside air

- rinse or wash vehicles after each unloading, ideally

- Minimize daily truck trips and returns

When receiving and storing

- keep odors in receiving and storing areas to a minimum to prevent odor spreading in the air

- place reception and storage rooms in continuous depression

- Provide a system of locks for truck traffic, based on the principle of the lock: a door must always separate the unloaded waste and the outside air

- install fume hoods where materials may come into contact with outdoor air, cover them or confine them

Source: Truck circulation system, ATEE

Other

- regularly check the reliability of the equipment and keep spare parts

- follow the plant’s maintenance steps and their frequency

- maintain the plant with rigor

4.Solutions associated with human resources

In addition to implementing technological or technical solutions, the project developer can call on specialized resources and the skills. This type of approach involves a variety of options: the project developer can hire a specialized resource as a consultant, train the staff to the problem of odors and ways of limiting them.

Examples: the application of solutions to manage odors

Here are some examples of possible ways to apply the previously mentioned solutions for odor management in a plant.

- Quasar Energy Group’s biogas plant:

Located in Ohio, the plant has hired a coordinator to respond to odor complaints coming from the local population. This role aimed to to monitor the company’s 8 biogas plants and to support the direct line for citizen complaints about odors. In this article, the company explains how they managed to stop unwanted plant odors usinga well-developed odor management strategy.

- Harvest Power Richmond Plant:

Located in Vancouver, the biogas plant produces compost and energy. It relies on a protocol for collecting data on odors, weather conditions, inputs, and process.

On-site operators warn their supervisor of changes in odors, and a dosimeter tracks them over time. All citizens’ complaints are documented, archived, analyzed, and compared, to meteorological data collected to ensure the continuous improvement of the process. Their odor management strategy for the plant [PDF, English, 510 KB] is available online.

Communicate with the community

Communicating with communities providing the right information at the right time is to prevent problems that may arise from the odors of a biogas plant. The project developer thus establishes harmonious and trusting relationships with the population living around the project sites.

This is why the development of a communication plan adapted to the needs of these communities is also part of the odor management process. Various means of communication can thus be implemented, such as:

- email or a direct line that citizens can use in case of unusual odors

- warning to the public when an episode of unwanted odors is coming

- maintenance of the developer’s commitments throughout the project

- participation of the population in the project design stage

This article discusses in greater depth the principles of social acceptability of biogas projects and collaboration with the population.

Need help? Our members can give you a hand!

Do you need help finding the ideal technology that will reduce the odors of your project? Several members of the BiogasWorld catalog could meet your needs.

Check out our catalog of companies and technologies.

To know more

- Guide of good practices for anaerobic digestion projects, ATEE

- Management of olfactory nuisances (presentation of SUEZ), APCAS

- Managing Odors at Anaerobic Digestion Plants, BioCycle

- Progressive Odor Management Plan for Harvest Power Richmond, Metro Vancouver